Umugqa Wokukhiqiza I-Margarine Ye-Bakery

Umugqa Wokukhiqiza I-Margarine Ye-Bakery

Umugqa Wokukhiqiza I-Margarine Ye-Bakery

Ividiyo Yokukhiqiza:https://www.youtube.com/watch?v=3cSJknMaYd8

Ibhikawozi umugqa wokukhiqiza imajarinikuhilela izigaba eziningana zokuguqula izinto zokusetshenziswa zibe umkhiqizo wamafutha osakazekayo, oxutshwe ne-emuls. Ngezansi umbono ophelele wezingxenye ezibalulekile kanye nezinqubo emgqeni ojwayelekile wokukhiqiza imajarini:

1. Ukulungiswa Kwezinto Ezingavuthiwe

Ukuhlanganiswa Kwamafutha Namafutha– Amafutha emifino (isundu, isoya, i-sunflower, imbewu ye-rapeseed) ayacwengwa, afakwe i-bleach, futhi asuswe iphunga (RBD). Amafutha aqinile (njenge-palm stearin) angangezwa ukuze kutholakale ukuthungwa.

- Ukuxuba Isigaba Samanzi– Amanzi, usawoti, ama-emulsifier (i-lecithin, i-mono/diglycerides), izithasiselo (i-potassium sorbate), kanye nezinongo kuyalungiswa.

2. Ukuhlanganiswa kwe-Emulsification

Izigaba zamafutha namanzi zixutshwe ngendlelaithangi lokuhlanganisangezinsimbi ezishefa kakhulu ukuze kwakheke i-pre-emulsion ezinzile (emanzini-ku-oyili).

Isilinganiso esijwayelekile: Amafutha angu-80%, isigaba samanzi esingu-20% (singahluka ngokusabalala kwamafutha aphansi).

3. Ukuhlanza (Ukushisa)

- I-emulsion ishiswa ukuze~70–80°Cku-plate heat exchanger ukubulala amagciwane nokuqinisekisa ukuthi ayafana.

4. Ukupholisa Nokwenza Ikristalu (Uhlelo Lokuvotela)

I-margarine idlula ku-i-scraped surface heat exchanger (SSHE)nomaumvoti, lapho ipholiswa khona ngokushesha ukuze ibangele ukwakheka kwama-crystallization kwamafutha:

- Iyunithi (Isilinda Sokupholisa): Ukupholisa kakhulu4–10°Cyakha amakristalu amancane amafutha.

- Iyunithi B (Isisebenzi se-Pin): Ukusebenza ngengxube kuqinisekisa ukuthungwa okubushelelezi kanye nokuqina.

- Ipayipi Lokuphumula (Iyunithi C): Ivumela ukuzinza kwekristalu.

5. Ukupakisha

- Imishini yokugcwalisa i-margarinefaka imajarini emabhafini, ezingxobeni zokusonga (zemajarini anamathelayo), noma ezitsheni ezinkulu.

- Ukulebula Nokubhala AmakhodiImininingwane yomkhiqizo kanye nezinombolo zeqoqo ziyaphrintwa.

6. Ukuhlolwa Kokulawulwa Kwekhwalithi

- Ukuthungwa Nokusabalala(i-penetrometry).

- Indawo Yokuncibilika(ukuqinisekisa ukuzinza ekushiseni kwegumbi).

- Ukuphepha Kwamagciwane(inani lamapuleti eliphelele, imvubelo/isikhunta).

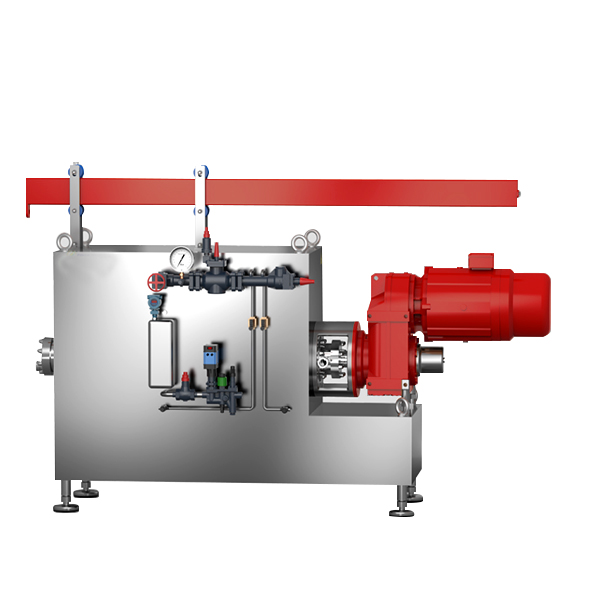

Imishini Eyinhloko Emugqeni We-Margarine

| Imishini | Umsebenzi |

| Ithangi Lokubumba | Ihlanganisa izigaba zamafutha/amanzi |

| I-Plate Heat Exchanger | I-Pasteurizes emulsion |

| Isishintshi Sokushisa Esingaphezulu Esikhuhliwe (iVotator) | Ukupholisa okusheshayo kanye nokukristala |

| Isisebenzi Sephini (Iyunithi B) | Yenza imajarini ibe nombala othambile |

| Imishini Yokugcwalisa Nokupakisha I-Margarine | Izingxenye zibe amayunithi okuthengisa |

Izinhlobo zeMargarine Ezikhiqizwayo

- I-Puff Pastry Margarine: I-plasticity ephezulu, isakhiwo esinezingqimba

- I-Margarine Yekhekhe: Izakhiwo ezikhilimu, zokungenisa umoya okuhle

- I-Margarine Engena Nge-Roll-in: Indawo ephezulu yokuncibilika kwe-lamination

- I-Margarine ye-Bakery Esebenzisa Zonke Izinhloso: Ilungele ukusetshenziswa okuhlukahlukene

Izinguquko Ezithuthukisiwe

- I-Margarine Engenayo I-Trans: Isebenzisa amafutha ahlanganisiwe esikhundleni se-hydrogenation engaphelele.

- I-Margarine Esekelwe Ezitshalweni: Izinhlobo ezingenayo ubisi (zezimakethe ze-vegan).

Ukuqaliswa Kwendawo