Umugqa Wokukhiqiza Isosi Ye-Custard

Umugqa Wokukhiqiza Isosi Ye-Custard

Umugqa Wokukhiqiza Isosi Ye-Custard

Ividiyo Yokukhiqiza:https://www.youtube.com/watch?v=AkAcycJx0pI

Aumugqa wokukhiqiza isosi ye-custardkuhilela uchungechunge lwezinqubo ezizenzakalelayo kanye nezizenzakalelayo ukuze kukhiqizwe isosi le-custard ngempumelelo, ngokuqhubekayo, nangokuhlanzeka. Ngezansi kunemininingwane eningiliziwe yezigaba ezijwayelekile emgqeni wokukhiqiza isosi le-custard:

1. Ukuphatha Nokulungiselela Izithako

- Ukwamukelwa Nokugcinwa Kobisi

- Ubisi olungaphekiwe luyamukelwa, luhlolwe ikhwalithi, bese lugcinwa ezitsheni eziqandisiwe.

- Okunye: Ubisi oluyimpuphu oluphinde lwakhiwa + amanzi (ukuhlala isikhathi eside eshalofini).

- Ukuphatha Ushukela Nokwenza Izinto Ezimnandi

- Ushukela, isiraphu yommbila, noma ezinye izinto ezinambithekayo ziyalinganiswa bese ziyancibilikiswa.

- Ukucutshungulwa Kwempuphu Yamaqanda Namaqanda

- Amaqanda acwebezelayo (afakwe i-pasteurized) noma i-egg powder axutshwa namanzi.

- Isitashi kanye nama-Stabilizer

- Isitashi sommbila, isitashi esiguquliwe, noma izithambisi (isib. i-carrageenan) zixutshwa kusengaphambili ukuze kuvinjelwe ukuqunjelwa.

- Izinongo Nezithasiselo

- I-vanilla, i-caramel, noma ezinye izinongo, kanye nezilondolozi (uma kudingeka), ziyalungiswa.

2. Ukuxuba Nokuhlanganisa

- Ukuxubana Okuqhubekayo noma Okuhlanganisiwe

- Izithako zihlanganiswa ku-umxube ogugile kakhulunomaithangi elihlanganisiwe kusengaphambilingaphansi kwamazinga okushisa alawulwayo (ukugwema ukujiya ngaphambi kwesikhathi).

- I-homogenization ingasetshenziswa ukuze kube nokuthungwa okubushelelezi.

3. Ukupheka Nokuhlanzwa Kwezithombo

- Ukupheka Okuqhubekayo (Isishintshi Sokushisa Esingaphezulu Esiklwebhekile)

- Ingxube ishiswa ukuze75–85°C (167–185°F)ukwenza kusebenze i-starch gelatinization futhi kuqinise isosi.

- Ukwenziwa kwe-Pasteurization (i-HTST noma i-Batch)

- Isikhathi Esifushane Esiphezulu Sokushisa (i-HTST) ku-72°C (161°F) imizuzwana eyi-15-20noma ukufakelwa kwe-batch ukuqinisekisa ukuphepha kwamagciwane.

- Isigaba Sokupholisa

- Ukupholisa okusheshayo kuya4–10°C (39–50°F)ukuyeka ukupheka okwengeziwe nokugcina ukuthungwa.

4. Ukuhlanganiswa kwe-Homogenization (Ongakukhetha)

- I-Homogenizer Enomfutho Ophezulu

- Isetshenziselwa ukuthungwa okubushelelezi kakhulu (kuvimbela ukuba luhlaza).

5. Ukugcwalisa Nokupakisha

- Imishini Yokugcwalisa Okuzenzakalelayo

- Ukugcwaliswa kwesikhwama(ngokuthengisa) nomaukugcwaliswa ngobuningi(ngesevisi yokudla).

- Ukugcwaliswa kwe-Aseptic(ukuphila isikhathi eside eshalofini) nomaukugcwalisa okushisayo(yesitoreji esizungezile).

- Amafomethi Okupakisha:

- Amabhodlela epulasitiki, amabhokisi, izikhwama, noma amathini.

- Ukuhlanza nge-nitrogen kungasetshenziswa ukwandisa isikhathi sokuphila kweshalofu.

6. Ukupholisa Nokugcina Izinto

- Ukushisa Okushisayo (uma kudingeka)

- Ukuze uthole i-custard efrijini, ukupholisa ngokushesha4°C (39°F).

- Indawo Yokugcina Izinto Ezibandayo

- Kugcinwe e-4°C (39°F)ukuze uthole i-custard entsha noma i-ambient yemikhiqizo ephathwe nge-UHT.

7. Ukulawulwa Kwekhwalithi Nokuhlolwa

- Ukuhlolwa Kokugoba(kusetshenziswa ama-viscometer).

- Ukuqapha i-pH(okuhlosiwe: ~6.0–6.5).

- Ukuhlolwa Kwezinto Eziphilayo(inani lamapuleti eliphelele, imvubelo/isikhunta).

- Ukuhlolwa Kwezinzwa(ukunambitha, ukuthungwa, umbala).

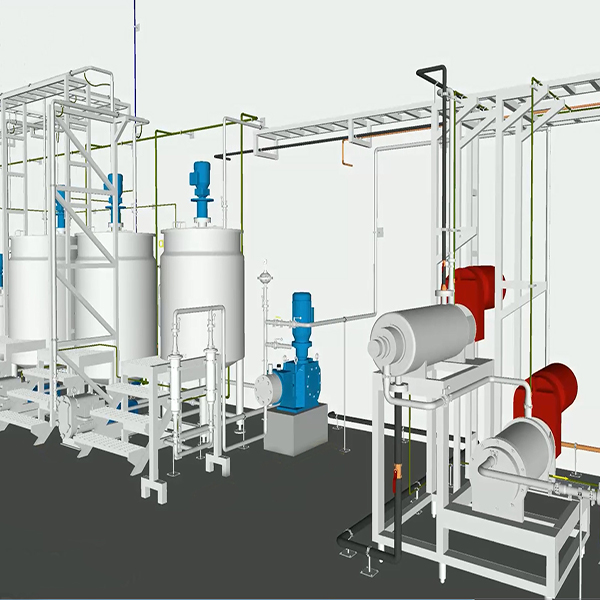

Imishini Eyinhloko Kumugqa Wokukhiqiza Isosi Ye-Custard

- Amathangi Okugcina Izinto(ngobisi, izithako eziwuketshezi).

- Izinhlelo Zokukala Nokulinganisa.

- Amathangi Okuxuba Asezingeni Eliphezulu Nama-Premix.

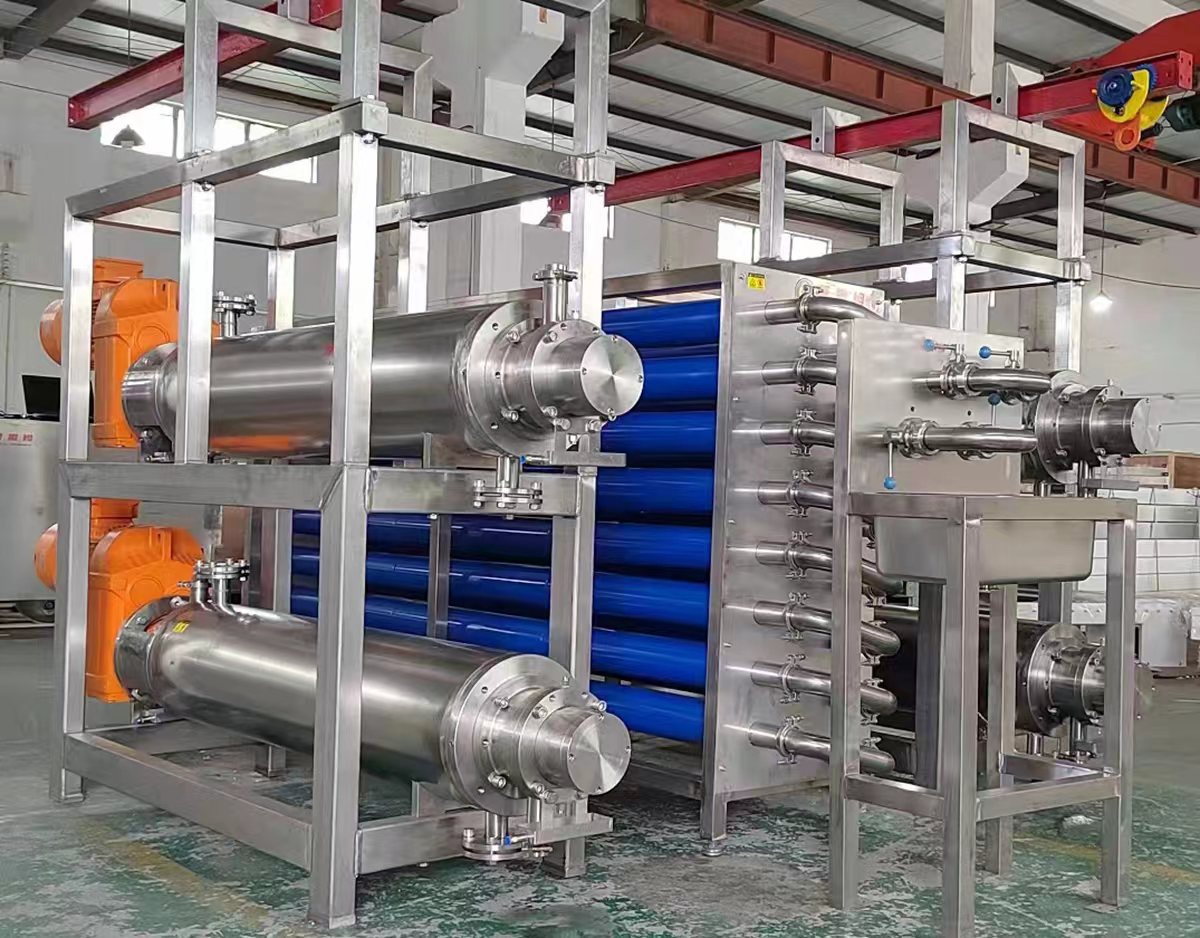

- I-Pasteurizer (i-HTST noma i-Batch).

- I-Scraped Surface Heat Exchanger (yokupheka).

- I-Homogenizer (ongakukhetha).

- Imishini Yokugcwalisa (i-piston, i-volumetric, noma i-aseptic).

- Imigudu Yokupholisa.

- Imishini Yokupakisha (ukuvala, ukulebula).

Izinhlobo ze-Custard Sauce Ezikhiqizwe

- I-Custard Efrijini(isikhathi esifushane sokuphila, ukunambitheka okusha).

- I-UHT Custard(ihlala isikhathi eside eshalofini, ihlanjululwe).

- Ingxube Ye-Custard Enophuphu(yokwakhiwa kabusha).

Ukuzenzakalela Nokusebenza Kahle

- Izinhlelo Zokulawula ze-PLCukuze kulawulwe izinga lokushisa elinembile kanye nokuxuba.

- Izinhlelo ze-CIP (Zokuhlanza Endaweni)kwenhlanzeko.

Ukuqaliswa Kwendawo