Inqubo Yokukhiqiza I-Margarine China Manufacturer

Inqubo Yokukhiqiza I-Margarine

Ividiyo Yokukhiqiza:https://www.youtube.com/watch?v=Zar71w0TUzM

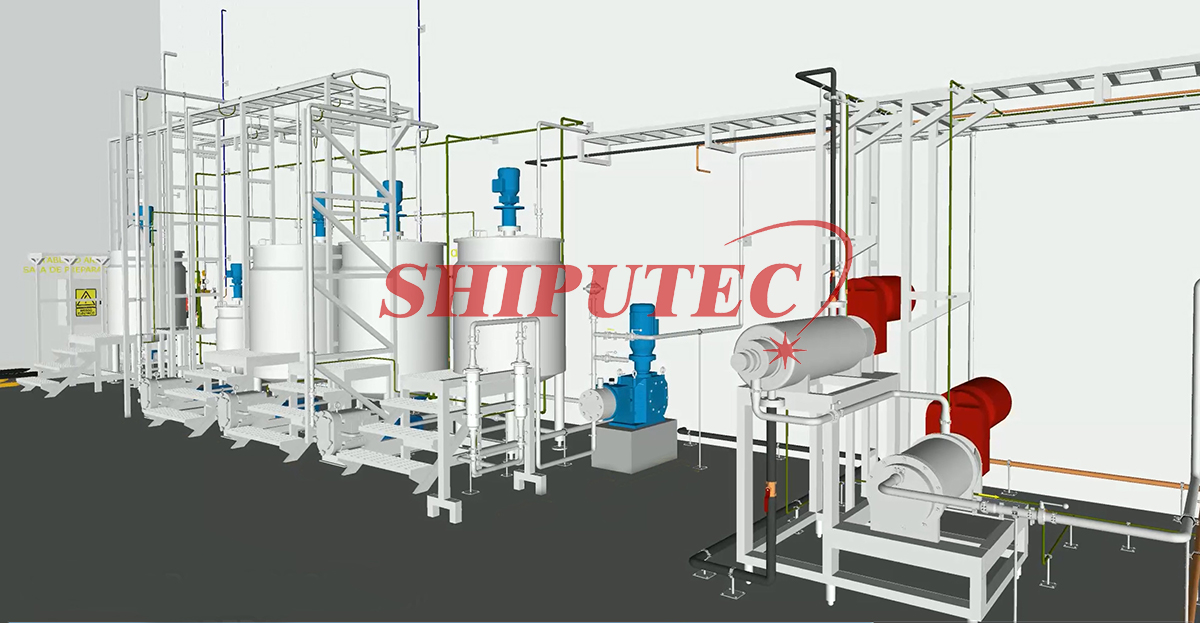

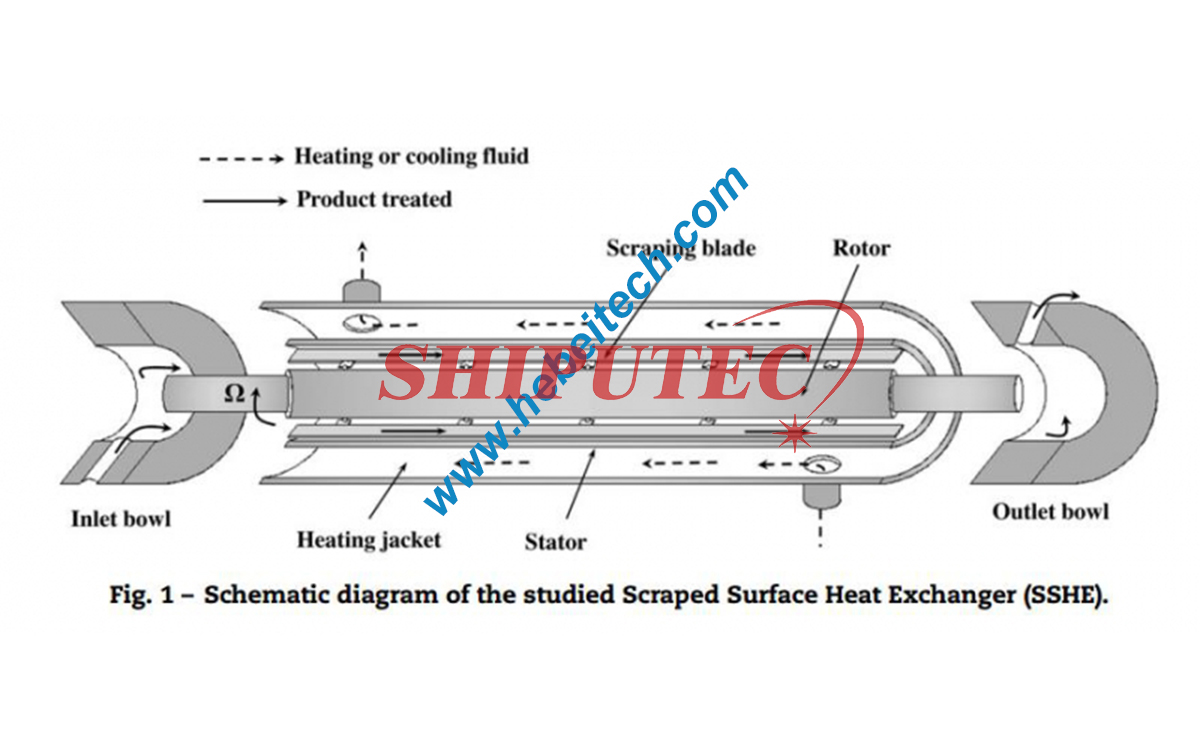

Ukukhiqizwa kwe-margarine kuhlanganisa izingxenye ezimbili: ukulungiswa kwezinto zokusetshenziswa kanye nokupholisa kanye nokwenza ipulasitiki. Imishini eyinhloko ihlanganisa amathangi okulungiselela, i-HP pump, i-votator (i-scraped surface heat exchanger), umshini we-pin rotor, i-friji unit, umshini wokugcwalisa i-margarine nokunye.

Inqubo yokuqala ingxube yesigaba samafutha kanye nesigaba samanzi, ukulinganiswa kanye nokuhlanganiswa kwengxube yesigaba samafutha kanye nesigaba samanzi, ukuze kulungiselelwe ukudla kwezinto zenqubo yokugcina. Inqubo yokugcina ukupholisa okuqhubekayo kwepulasitiki kanye nokupakishwa komkhiqizo.

Inqubo yokulungisa izinto zokusetshenziswa kwe-margarine iboniswe kuMfanekiso 1:

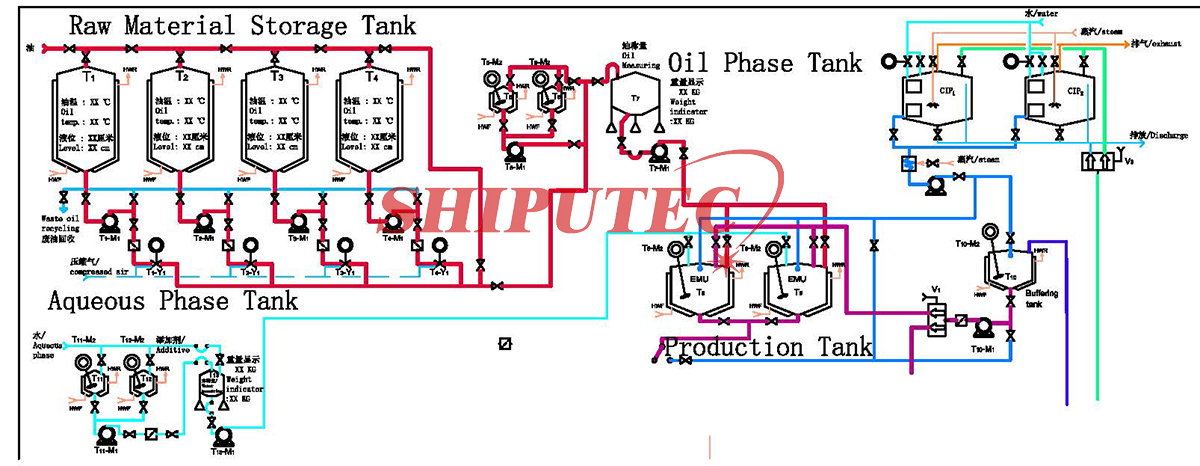

- 1.Ubisi oluvutshiwe

Ifomula ethile ye-margarine yokwengeza ubisi, kanye nobisi ngemva kokubiliswa kwamagciwane e-lactic acid kungakhiqiza ukunambitheka okufanayo kokhilimu wemvelo, ngakho-ke imboni ixube ubisi olubilisiwe namanzi.

- 2.Ukuxuba amanzi

Izithasiselo zamanzi kanye nezincibilikisiwe emanzini ezikwifomula ye-margarine, njengobisi olubilisiwe, usawoti, izithako zokugcina, njll., zengezwa ekuxubeni kwesigaba samanzi kanye nethangi lokulinganisa ngesilinganiso esinqunyiwe ukuze kuxutshwe futhi kuhlanganiswe, ukuze izingxenye zesigaba samanzi zincibilikiswe zibe yisisombululo esifanayo.

- 3.Ukuxuba isigaba samafutha

Uwoyela ongahluziwe onezincazelo ezahlukene uqala uxutshwe ethangini lokuxuba uwoyela ngokwesilinganiso esibekiwe, bese kuthi izithasiselo ezincibilika uwoyela, njenge-emulsifier, i-antioxidant, i-pigment encibilika uwoyela, i-cellulose encibilika uwoyela, njll., zengezwe esigabeni samafutha ngokwesilinganiso, zixutshwe nethangi lokulinganisa, bese zivuselelwa ukuze kwakhiwe isigaba sawoyela esifanayo.

- 4.I-emulsion

Inhloso ye-emulsification ye-margarine ukwenza isigaba samanzi sihlakazeke ngokulinganayo nangokuzinzile esigabeni samafutha, kanti izinga lokusabalala kwesigaba samanzi linomthelela omkhulu kwikhwalithi yomkhiqizo. Ngenxa yokuthi ukunambitheka kwe-margarine kuhlobene eduze nosayizi wezinhlayiya zesigaba samanzi, ukusabalala kwamagciwane kwenzeka esigabeni samanzi, ubukhulu bamagciwane ajwayelekile buyi-1-5 microns, ngakho amaconsi amanzi kuma-microns ayi-10-20 noma ububanzi obuncane angakhawulela ukusabalala kwamagciwane, ngakho ukusabalala kwesigaba samanzi kuncane kakhulu, izinhlayiya zesigaba samanzi zincane kakhulu zizokwenza i-margarine ilahlekelwe ukunambitheka; Ukusabalala akwanele, izinhlayiya zesigaba samanzi zikhulu kakhulu, kuzokwenza i-margarine ibe yi-metamorphism eyonakele. Ubudlelwano phakathi kwezinga lokusabalala kwesigaba samanzi ku-margarine kanye nohlobo lomkhiqizo bucishe bube kanje:

| 水滴直径 Ubukhulu bokwehla kwamanzi (微米 micrometer) | 人造奶油性质 (Taste of Margarine) |

| ngaphansi kuka-1 (cishe u-80-85% wesigaba samanzi) | Ukunambitheka okunzima nokuncane |

| 30-40 (ngaphansi kuka-1% wesigaba samanzi) | Ukunambitheka okuhle, kulula ukubola |

| 1-5 (cishe u-95% wesigaba samanzi) | Ukunambitheka okuhle, akulula ukubola |

| 5-10 (cishe u-4% wesigaba samanzi) | |

| 10-20 (cishe i-1% yesigaba samanzi) |

Kungabonakala ukuthi ukusebenza kwe-emulsification kufanele kufinyelele izinga elithile lezidingo zokuhlakazeka.

Inhloso yokuxuba isigaba samanzi kanye nesigaba samafutha ngokwehlukana nangokulinganayo nesigaba sangaphambilini ukuqinisekisa ukuvumelana okufanayo kwe-emulsion yonke ngemva kokuhlanganiswa kwe-emulsification kanye nokuhlanganiswa kwezigaba ezimbili zamafutha namanzi. Ukuxuba i-emulsification, inkinga yokusebenza ingama-degree angu-50-60, isigaba samanzi sengezwa esigabeni samafutha esilinganisiwe, emjikelezweni wokuxuba ngomshini noma wepompo, isigaba samanzi sihlakazeke ngokuphelele esigabeni samafutha, ukwakheka kwe-latex. Kodwa lolu hlobo lwe-latex liquid aluzinzile kakhulu, ukuyeka ukuxuba kungase kube yinto yokuhlukaniswa kwamafutha namanzi endaweni yokudlala.

Ngemva kokulethwa kwe-emulsion exubile, inqubo yokupholisa nokwenza ipulasitiki yenziwa kuze kube yilapho umkhiqizo upakishwa.

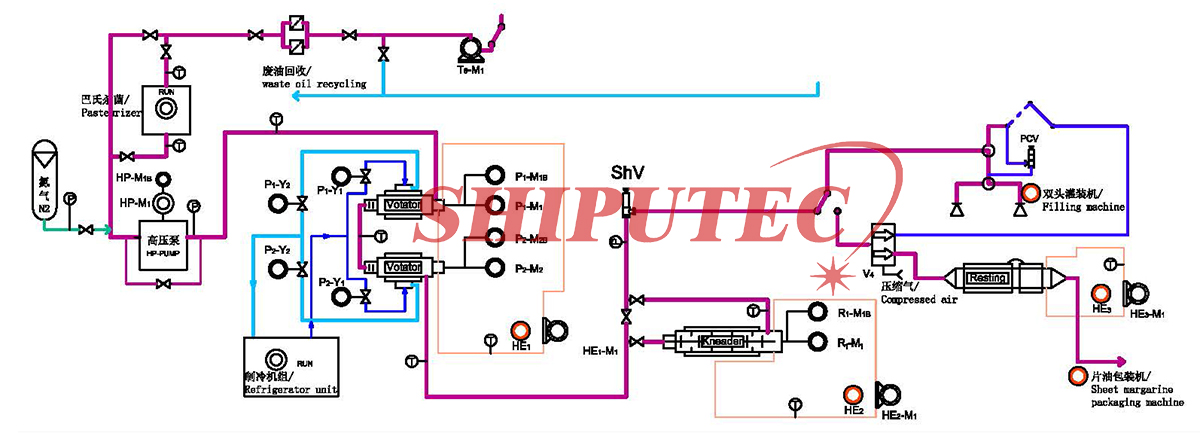

I-emulsion kumele ipholiswe futhi yenziwe ipulasitiki ukuze ikhiqize umkhiqizo we-margarine oguquguqukayo. Njengamanje, isebenzisa kakhulu idivayisi yokupholisa eqhubekayo evaliwe, okuhlanganisa i-votator noma ebizwa ngokuthi i-scraped surface heat exchanger (iyunithi A), umshini we-pin rotor noma umshini wokuxova (iyunithi C) kanye ne-resting tube (iyunithi B). Inqubo yobuchwepheshe iboniswe kuMfanekiso 2:

Le sethi yemishini inezici ezilandelayo:

1. Ukusebenza okuqhubekayo komoya okungenamoya okuphezulu

I-emulsion exutshwe ngaphambilini ifakwa kwisilinda yokucima umlilo ngephampu yokucindezela okuphezulu yomvoti. Ukucindezela okuphezulu kunganqoba ukumelana kuyo yonke iyunithi, ngaphezu kokusebenza kokucindezela okuphezulu kungenza umkhiqizo ube mncane futhi ubushelelezi. Ukusebenza okuvaliwe kungavimbela umoya nomoya ngenxa yokucima kanye nokujiya kwamanzi axutshwe ne-emulsion, kuqinisekiswe izidingo zempilo yomkhiqizo, kunciphise ukulahleka kwesiqandisi.

2. Ukucima kanye nokuhlanganisa i-emuls

I-emulsion icishwa nge-ammonia noma i-Freon ku-votator ukuze kuphole i-emulsion ngokushesha, ukuze kukhiqizwe izinhlayiya ezincane zekristalu, ngokuvamile ezingama-micron angu-1-5, ukuze ukunambitheka kube mnandi. Ngaphezu kwalokho, i-scraper ku-shaft ejikelezayo ku-votator ixhumene eduze nodonga lwangaphakathi lwesilinda, ngakho-ke i-scraper esebenza ayikwazi nje kuphela ukuklwebha i-crystallization enamathele odongeni lwangaphakathi, kodwa futhi yenze i-emulsion ihlakazeke ukuze ihlangabezane nezidingo ze-emulsification zethoni.

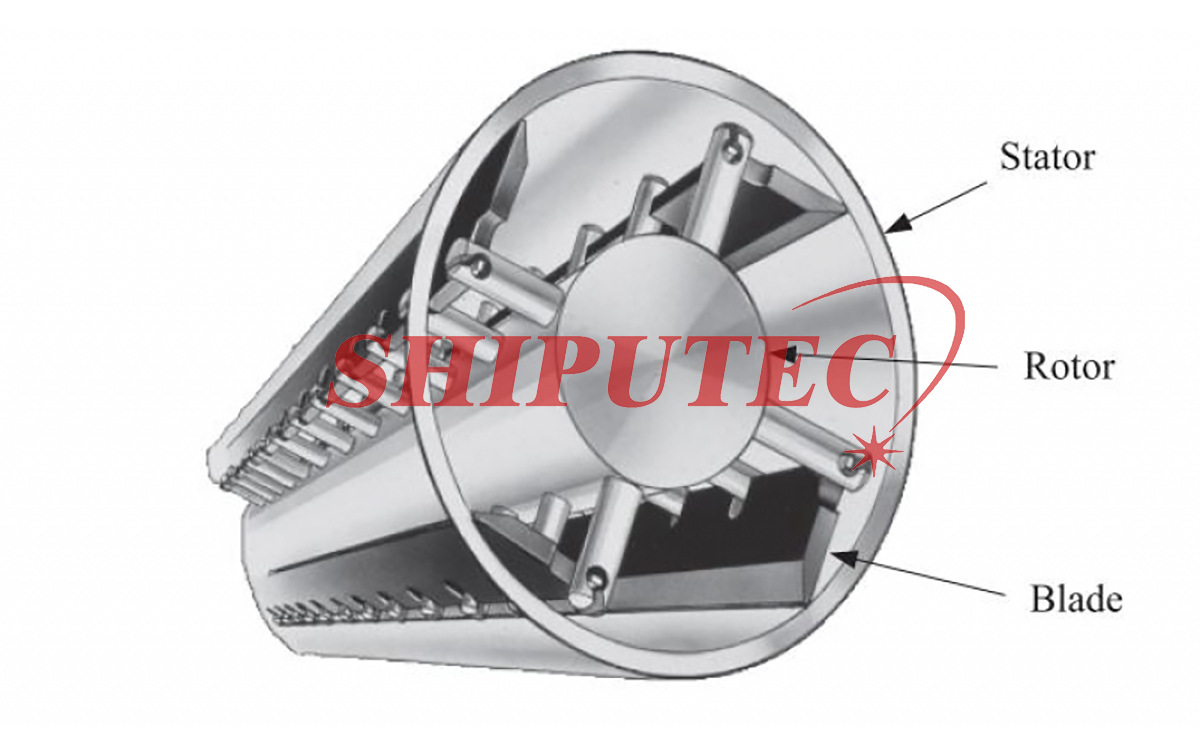

3. Ukuxova nokususa ugqinsi (umshini we-pin rotor)

Nakuba i-emulsion epholiswe yi-votator isiqalile ukukhiqiza i-crystallization, kusadingeka ikhule phakathi nesikhathi esithile. Uma i-emulsion ivunyelwe ukuthi i-crystal iphumule, kuzokwakhiwa inethiwekhi yamakristalu aqinile e-lipid. Umphumela uba ukuthi i-emulsion epholisiwe izokwakha isisindo esiqinile kakhulu esingena-plasticity. Ngakho-ke, ukuze kutholakale imikhiqizo ye-margarine ene-plasticity ethile, isakhiwo senethiwekhi kumele siphulwe ngezindlela zomshini ngaphambi kokuba i-emulsion yakhe isakhiwo senethiwekhi iyonke, ukuze kufezwe umphumela wokunciphisa ukuqina. Ukuxova nokususa ukuqina kwenziwa kakhulu emshinini we-pin rotor.

Iyunithi A (i-votator) empeleni iyidivayisi yokupholisa i-scraper. I-emulsion iqhutshwa kuyunithi A evaliwe (i-votator) ngepompo yokucindezela okuphezulu. Izinto zidlula emseleni ophakathi kwesilinda sokupholisa kanye nomgodi ojikelezayo, futhi izinga lokushisa lezinto lehla ngokushesha ngokucinywa kwendawo yokupholisa. Imigqa emibili yama-scraper ihlelwe ebusweni bomgodi. Amakristalu akhiwe ebusweni bangaphakathi bomgodi akhuhlwa yi-scraper ejikelezayo esheshayo ukuze ahlale eveza indawo entsha yokupholisa futhi agcine ukudluliselwa kokushisa okusebenzayo. I-emulsion ingahlakazeka ngaphansi kwesenzo se-scraper. Lapho izinto zidlula kuyunithi A (i-votator), izinga lokushisa lehla liye kuma-degrees ayi-10-20, okuphansi kunephuzu lokuncibilika kwamafutha. Nakuba uwoyela uqala ukukristala, awukakhi isimo esiqinile. Ngalesi sikhathi, i-emulsion isesimweni sokupholisa futhi iyiketshezi elijiyile.

I-axis yokujikeleza yeyunithi A (i-votator) ayinalutho. Ngesikhathi sokusebenza, amanzi ashisayo angama-degrees angu-50-60 athelwa enkabeni ye-axis yokujikeleza ukuvimbela ukwakheka kwamakristalu okuboshelwe futhi okuphiliswe ku-axis futhi kubangele ukuvaleka.

Iyunithi C (umshini we-pin rotor) iyithuluzi lokuxova nokususa ukujiya, njengoba kuboniswe esithombeni esingenhla. Imigqa emibili yama-bolt ensimbi ifakiwe ku-shaft ejikelezayo, futhi umugqa wama-bolt ensimbi agxilile ufakwe odongeni lwangaphakathi lwesilinda, ahlanganiswe nama-bolt ensimbi ku-shaft futhi awathintani. Lapho i-shaft ijikeleza ngesivinini esikhulu, ama-bolt ensimbi ku-shaft adlula isikhala sama-bolt ensimbi agxilile, futhi izinto zixovwe ngokuphelele. Ngaphansi kwalesi senzo, ingakhuthaza ukukhula kwama-crystals, ibhubhise isakhiwo senethiwekhi ye-crystal, yakhe ama-crystals angaqhubeki, inciphise ukuvumelana, futhi yandise i-plasticity.

Iyunithi C (umshini we-pin rotor) idlala kuphela umphumela oqinile wokuxova ngobusuku obubandayo kakhulu, ngakho idinga ukulondolozwa kokushisa kuphela futhi ayidingi ukupholisa. Njengoba ukushisa kwe-crystallization kukhishwa (cishe ama-50KCAL/KG), kanye nokushisa okukhiqizwa ukuxova, izinga lokushisa lokukhipha leyunithi C (pin rotor macjhine) liphakeme kunelokushisa lokuphakelayo. Ngalesi sikhathi, i-crystallization isiphelile cishe ngo-70%, kodwa isathambile. Umkhiqizo wokugcina ukhishwa nge-extrusion valve, futhi uzoba nzima ngemva kwesikhathi esithile.

Ngemva kokuba i-margarine ithunyelwe kusuka ku-C unit (umshini we-pin rotor), idinga ukuphathwa ngokushisa ekushiseni okuthile. Ngokuvamile, umkhiqizo ubekwa ekushiseni kwama-degrees ayi-10 ngaphansi kwephuzu lokuncibilika isikhathi esingaphezu kwamahora angu-48. Lokhu kwelashwa kubizwa ngokuthi ukuvuthwa. Umkhiqizo ophekiwe ungathunyelwa ngqo esitshalweni sokucubungula ukudla ukuze usetshenziswe.

Ukuqaliswa Kwendawo