I-Margarine Production Technology

ISIFINYEZO ESIPHEZULU

Izinkampani zokudla namuhla zifana namanye amabhizinisi akhiqizayo angagxili nje kuphela ekwethembekeni naseqophelweni lemishini yokucubungula ukudla kodwa nasezinsizeni ezihlukahlukene umphakeli wemishini yokucubungula angayiletha. Ngaphandle kwemigqa yokucubungula ephumelelayo esiyilethayo, singaba uzakwethu kusukela kumbono wokuqala noma isigaba sephrojekthi kuya esigabeni sokugcina sokugunyazwa, singakhohlwa isevisi ebalulekile yangemva kwemakethe.

AbakwaShiputec banesipiliyoni seminyaka engaphezu kwengama-20 embonini yokucubungula ukudla kanye nokupakisha.

ISINGENISO KUBUCHWEPHESHE BETHU

UMBONO NOKUZIBOPHO

Ingxenye ye-Shiputec idizayina, ikhiqize futhi izimakethe icubungula izixazululo zobunjiniyela nezokuzenzekelayo ezimbonini zobisi, zokudla, iziphuzo, zasolwandle, ezemithi nezokunakekelwa komuntu siqu ngokusebenzisa imisebenzi yayo yomhlaba wonke.

Sizibophezele ekusizeni amakhasimende ethu emhlabeni wonke ukuthuthukisa ukusebenza kanye nenzuzo yefekthri yabo nezinqubo. Sifinyelela lokhu ngokunikeza inhlobonhlobo yemikhiqizo nezisombululo kusukela ezingxenyeni zobunjiniyela kuya ekuklanyweni kwezitshalo zezinqubo eziphelele ezisekelwa izinhlelo zokusebenza ezihamba phambili emhlabeni nobungcweti bokuthuthukisa.

Siyaqhubeka nokusiza amakhasimende ethu ukuthi athuthukise ukusebenza kanye nokwenza inzuzo kweplanti yawo kukho konke ukuphila kwayo kwesevisi ngamasevisi okusekela aklanyelwe izidingo zawo zomuntu ngamunye ngokusebenzisa isevisi yamakhasimende edidiyelwe kanye nenethiwekhi yezingxenye eziyisipele.

UKUGXILA KWEKHASIMENDE

I-Shiputec ithuthukisa, ikhiqize futhi ifake imigqa yokucubungula yesimanje, esebenza kahle kakhulu futhi enokwethenjelwa embonini yokudla. Ukuze kukhiqizwe imikhiqizo yamafutha acwebezelayo njengemajarini, ibhotela, ukusabalala kanye nokufinyeza iShiputec inikeza izixazululo ezihlanganisa imigqa yenqubo yemikhiqizo yokudla e-emulsified efana nemayonnaise, amasoso nezindwangu zokugqoka.

UKHIQIZWA KWE-MARGARINE

Imajarini kanye nemikhiqizo ehlobene nayo iqukethe isigaba samanzi kanye nesigaba samafutha futhi ngaleyo ndlela ingabonakala njengama-emulsion wamanzi ku-oyili (W/O) lapho isigaba samanzi sihlakazwa kahle njengamaconsi esigabeni samafutha esiqhubekayo. Kuye ngokusetshenziswa komkhiqizo, ukwakheka kwesigaba samafutha kanye nenqubo yokukhiqiza kukhethwa ngokufanele.

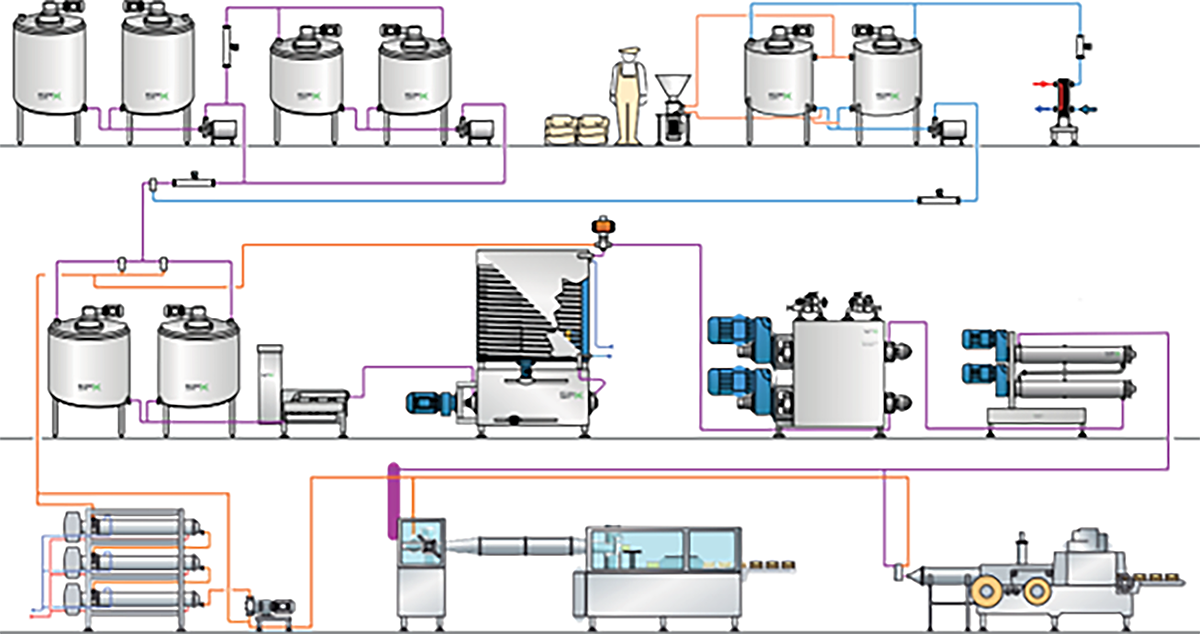

Ngaphandle kwemishini yokwenza ikristalu, indawo yesimanje yokukhiqiza imajarini kanye nemikhiqizo ehlobene nayo izobandakanya amathangi ahlukahlukene okugcina uwoyela kanye ne-emulsifier, isigaba samanzi kanye nokulungiswa kwe-emulsion; ubukhulu kanye nenani lamathangi kubalwa ngokusekelwe kumthamo wesitshalo kanye nephothifoliyo yomkhiqizo. Lesi sikhungo sihlanganisa neyunithi ye-pasteurization kanye nendawo yokuncibilikisa. Ngakho, inqubo yokukhiqiza ingahlukaniswa ngokujwayelekile ibe yizinqubo ezincane ezilandelayo (sicela ubheke umdwebo 1):

UKULUNGISWA KWESIGABA SAMANZI KANYE NESIGABA SAMAFUTHA (IZON 1)

Isigaba samanzi sivamise ukulungiselelwa i-batch-wise ethangini lesigaba samanzi. Amanzi kufanele abe sezingeni elihle lokuphuza. Uma amanzi ekhwalithi yokuphuza engenakuqinisekiswa, amanzi angenziwa ekwelashweni ngokusebenzisa isib. i-UV noma isistimu yokuhlunga.

Ngaphandle kwamanzi, isigaba samanzi singabandakanya usawoti noma i-brine, amaprotheni obisi (i-margarine yetafula kanye nokusabalala kwamafutha aphansi), ushukela (i-puff pastry), ama-stabilizers (ama-fat fats ancishisiwe futhi aphansi), ama-preservatives kanye nama-flavour ancibilikayo emanzini.

Izithako eziyinhloko esigabeni samafutha, inhlanganisela yamafutha, ngokuvamile ihlanganisa inhlanganisela yamafutha namafutha ahlukene. Ukuze kuzuzwe imajarini enezici ezidingekayo nokusebenza, isilinganiso samafutha namafutha enhlanganisela yamafutha sinquma ukusebenza komkhiqizo wokugcina.

Amafutha ahlukahlukene namafutha, okungaba njengengxube yamafutha noma amafutha awodwa, agcinwa kumathangi okugcina uwoyela ngokuvamile abekwe ngaphandle kwendawo yokukhiqiza. Lezi zigcinwa ezingeni lokushisa elizinzile lesitoreji ngaphezu kwendawo yokuncibilika kwamafutha nangaphansi kokuyaluza ukuze kugwenywe ukuhlukaniswa kwamafutha nokuvumela ukuphatha kalula.

Ngaphandle kwenhlanganisela yamafutha, isigaba samafutha ngokuvamile siqukethe izithako ezincane ezincibilikayo ezifana ne-emulsifier, i-lecithin, ukunambitheka, umbala kanye nama-antioxidants. Lezi zithako ezincane zincibilika ku-fat blend ngaphambi kokuba isigaba samanzi sengezwe, ngaleyo ndlela ngaphambi kwenqubo ye-emulsification.

UKULUNGISWA kwe-EMULION ( ZONE 2 )

I-emulsion ilungiswa ngokudlulisela amafutha ahlukahlukene kanye namafutha noma amafutha ahlanganiswe ethangini le-emulsion. Ngokuvamile, amafutha ancibilikayo aphezulu noma ama-fat blends ayengezwa kuqala alandelwe amafutha ancibilikayo aphansi kanye namafutha angama-liquid. Ukuze uqedele ukulungiswa kwesigaba samafutha, i-emulsifier nezinye izithako ezincane ezincibilika ngamafutha zengezwa ekuhlanganiseni kwamafutha. Lapho zonke izithako zesigaba samafutha zixubene kahle, isigaba samanzi siyengezwa futhi i-emulsion idalwe ngaphansi kokuxuba okunamandla kodwa okulawulwayo.

Amasistimu ahlukene angasetshenziswa ukukala izithako ezihlukahlukene ze-emulsion lapho ezimbili zisebenza ngokulandelana:

Isistimu yemitha yokugeleza

Uhlelo lwethangi lokukala

Uhlelo oluqhubekayo lwe-in-line emulsification luyisixazululo esingathandwa kakhulu kodwa esisetshenziswa eg. Lolu hlelo lusebenzisa amaphampu we-dosing kanye namamitha okugeleza kwenqwaba ukulawula isilinganiso sezigaba ezingeziwe zibe ithangi elincane le-emulsion.

Lezi zinhlelo ezibalwe ngenhla zingalawulwa ngokuphelele ngokuzenzakalelayo. Ezinye izitshalo ezindala, nokho, zisenazo izinhlelo zokulungisa i-emulsion ezilawulwa mathupha kodwa lezi zidinga umsebenzi futhi akunconywa ukuthi zifakwe namuhla ngenxa yemithetho eqinile yokulandela umkhondo.

Uhlelo lwemitha yokugeleza lusekelwe ekulungiseleleni i-emulsion ehlakaniphile nge-batch lapho izigaba nezithako ezihlukahlukene zikalwa ngamamitha okugeleza okukhulu uma zidluliswa zisuka emathangini okulungiselela izigaba ezihlukahlukene ziyiswa ethangini le-emulsion. Ukunemba kwalolu hlelo kungu-+/-0.3%. Lolu hlelo lubonakala ngokungazweli kumathonya angaphandle njengokudlidliza nokungcola.

Uhlelo lwethangi lokukala lufana nesistimu yemitha yokugeleza esekelwe ekulungiseleleni i-emulsion ehlakaniphile. Lapha amanani wezithako nezigaba zengezwa ngqo ethangini le-emulsion elifakwe kumaseli omthwalo alawula amanani angezwe ethangini.

Ngokuvamile, uhlelo lwamathangi amabili lusetshenziselwa ukulungiselela i-emulsion ukuze ukwazi ukuqhuba umugqa we-crystallization ngokuqhubekayo. Ithangi ngalinye lisebenza njengethangi lokulungiselela kanye ne-buffer (ithangi le-emulsion), ngakho-ke umugqa we-crystallization uzophakelwa kusuka ethangini elilodwa ngenkathi inqwaba entsha izolungiswa kwelinye futhi ngokuphambene nalokho. Lokhu kubizwa ngokuthi i-flip-flop system.

Isixazululo lapho i-emulsion ilungiswa ethangini elilodwa futhi uma isilungile idluliselwa ku-tank ye-buffer kusukela lapho umugqa we-crystallization unikezwa khona nakho kuyinketho. Lolu hlelo lubizwa nge-premix/buffer system.

I-PASTEURIZATION ( ZONE 3 )

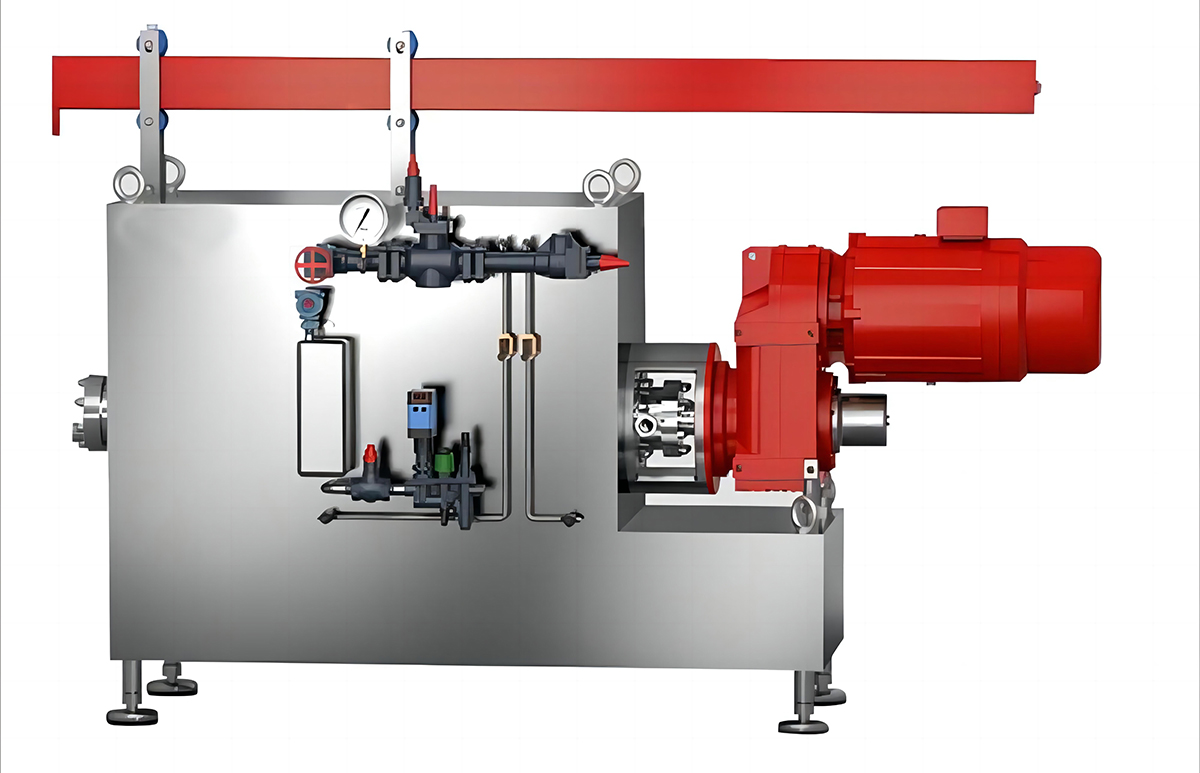

Kusuka kubhafa ithangi i-emulsion ivamise ukumponthwa ngokuqhubekayo ngokusebenzisa isishintshi sokushisa sepuleti (PHE) noma isishintshi sokushisa esikhishwe ngomfutho ophansi (i-SSHE), noma i-SSHE yomfutho ophezulu we-pasteurization ngaphambi kokungena emugqeni wecrystallization.

Ngemikhiqizo yamafutha agcwele i-PHE ivame ukusetshenziswa. Ezinguqulweni zamafutha aphansi lapho i-emulsion kulindeleke ukuthi ibonise i-viscosity ephakeme ngokuqhathaniswa kanye nama-emulsions azwela ukushisa (isb ama-emulsions ane-protein ephezulu) uhlelo lwe-SPX njengesisombululo sokucindezela okuphansi noma i-SPX-PLUS njengesixazululo sokucindezela okuphezulu kunconywa.

Inqubo ye-pasteurization inezinzuzo eziningana. Iqinisekisa ukuvinjelwa kokukhula kwebhaktheriya nokukhula kwamanye ama-micro-organisms, ngaleyo ndlela ithuthukise ukuzinza kwe-microbiological ye-emulsion. I-pasteurization yesigaba samanzi kungenzeka kuphela, kodwa ukufakwa kwe-emulsion ephelele kuyakhethwa kusukela inqubo ye-pasteurization ye-emulsion izonciphisa isikhathi sokuhlala kusukela kumkhiqizo ongenayo i-pasteurized ukugcwalisa noma ukupakisha umkhiqizo wokugcina. Futhi, umkhiqizo uphathwa ngenqubo ye-in-line kusuka ku-pasteurization kuya ekugcwalisweni noma ukupakishwa komkhiqizo wokugcina futhi ukufakwa kwe-pasteurization kwanoma iyiphi impahla yokusebenza kabusha kuqinisekiswa lapho i-emulsion ephelele i-pasteurized.

Ngaphezu kwalokho, i-pasteurization ye-emulsion ephelele iqinisekisa ukuthi i-emulsion idliwe emgqeni we-crystallization endaweni yokushisa eqhubekayo ekufezeni imingcele yokucubungula njalo, izinga lokushisa lomkhiqizo kanye nokuthungwa komkhiqizo. Ukwengeza, ukuvela kwe-emulsion yangaphambi kwekristalu ephakelwa imishini ye-crystallization ivinjelwa lapho i-emulsion ifakwe kahle futhi yondliwe empompini yokucindezela okuphezulu ekushiseni kwe-5-10 ° C ngaphezu kwendawo yokuncibilika yesigaba samafutha.

Inqubo evamile ye-pasteurization izoba ngemva kokulungiswa kwe-emulsion ku-45-55 ° C kufaka phakathi ukushisa nokubamba ukulandelana kwe-emulsion ku-75-85 ° C nge-16 sec. futhi kamuva inqubo yokupholisa izinga lokushisa elingu-45-55°C. Izinga lokushisa lokugcina lincike endaweni yokuncibilika kwesigaba samafutha: lapho izinga lokuncibilika liphakeme, izinga lokushisa liphezulu.

UKUCHITHA, UKUKHISALA NOKUGUQA (IZONA 4)

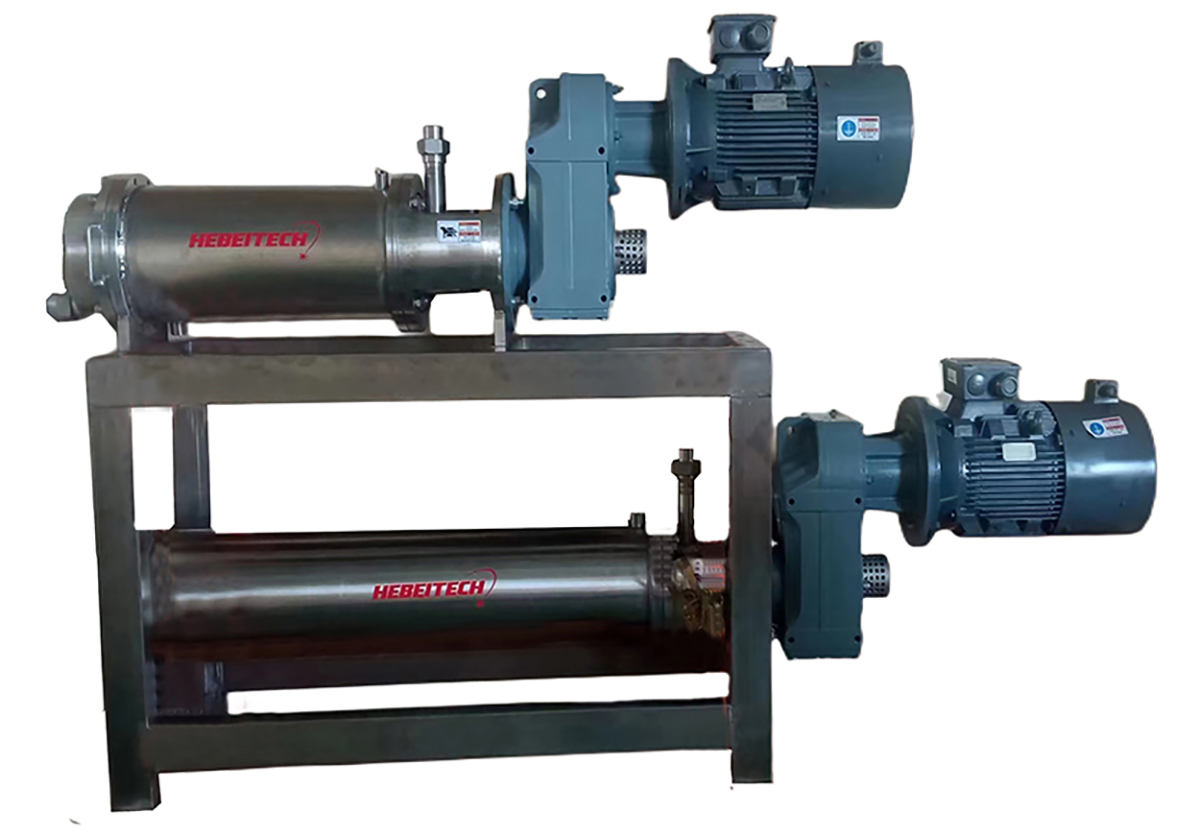

I-emulsion iphonswa emgqeni we-crystallization ngokusebenzisa iphampu yepiston yokucindezela okukhulu (HPP). Ulayini wecrystallization wokukhiqiza imajarini kanye nemikhiqizo ehlobene ngokuvamile uqukethe i-SSHE yokucindezela okuphezulu epholiswa ngemidiya yokupholisa yohlobo lwe-ammonia noma i-Freon. Imishini ye-pin rotor kanye/noma amakristalu aphakathi nendawo kuvame ukufakwa emgqeni ukuze kwengezwe umfutho wokuxova owengeziwe kanye nesikhathi sokukhiqizwa kwemikhiqizo yepulasitiki. I-tube yokuphumula iyisinyathelo sokugcina somugqa we-crystallization futhi ifakwe kuphela uma umkhiqizo ugcwele.

Inhliziyo yomugqa we-crystallization iyingcindezi ephezulu ye-SSHE, lapho i-emulsion efudumele ipholile kakhulu futhi icwebezeliswe endaweni engaphakathi yeshubhu elibandayo. I-emulsion ikhishwe ngokuphumelelayo ngama-scrapers ajikelezayo, ngaleyo ndlela i-emulsion ipholile futhi ixutshwe kanyekanye. Lapho amafutha aku-emulsion ecwebezela, amakristalu amafutha akha inethiwekhi enezinhlangothi ezintathu ebamba amaconsi amanzi kanye namafutha awuketshezi, okuholela emikhiqizweni enezakhiwo zepulasitiki semi-solid nature.

Kuya ohlotsheni lomkhiqizo ozokhiqizwa kanye nohlobo lwamafutha asetshenziselwa umkhiqizo othile, ukucushwa komugqa wokucwebezelisa (okungukuthi ukuhleleka kwamashubhu okupholisa kanye nemishini ye-pin rotor) kungalungiswa ukuze kuhlinzekwe ukucushwa okuphelele komkhiqizo othile.

Njengoba umugqa we-crystallization ngokuvamile ukhiqiza ngaphezu komkhiqizo owodwa wamafutha othize, i-SSHE ngokuvamile iqukethe izingxenye ezimbili noma ngaphezulu zokupholisa noma amashubhu abandayo ukuze kuhlangatshezwane nezidingo zomugqa we-crystallization oguquguqukayo. Lapho ukhiqiza imikhiqizo ehlukene yamafutha acwebezelayo yenhlanganisela yamafutha ahlukahlukene, ukuguquguquka kuyadingeka njengoba izici zokucwebezela kwezingxube zingase zehluke kusukela ekuhlanganiseni okukodwa kuya kwenye.

Inqubo ye-crystallization, izimo zokucubungula kanye nemingcele yokucubungula kunethonya elikhulu ezicini zemajarini yokugcina kanye nemikhiqizo yokusabalalisa. Lapho uklama umugqa we-crystallization, kubalulekile ukukhomba izici zemikhiqizo ehlelelwe ukwakhiwa emgqeni. Ukuze kuvikelwe utshalomali lwesikhathi esizayo, ukuguquguquka kolayini kanye nemingcele yokucubungula ngayinye iyadingeka, njengoba uhla lwemikhiqizo enenzuzo lungashintsha ngokuhamba kwesikhathi kanye nezinto ezingavuthiwe.

Umthamo womugqa unqunywa indawo yokupholisa etholakalayo ye-SSHE. Imishini yosayizi abahlukene iyatholakala kusukela kolayini abaphansi ukuya komthamo omkhulu. Futhi amadigri ahlukahlukene okuguquguquka ayatholakala kusukela kumishini yeshubhu eyodwa kuya emigqeni yamashubhu amaningi, ngaleyo ndlela imigqa yokucubungula eguquguquka kakhulu.

Ngemuva kokuthi umkhiqizo ubanda ku-SSHE, ungena emshinini we-pin rotor kanye/noma amakristalu aphakathi nendawo lapho uxova khona isikhathi esithile futhi ngamandla athile ukuze kusize ukukhuthazwa kwenethiwekhi ye-three-dimensional, okuyinto ezingeni le-macroscopic isakhiwo sepulasitiki. Uma umkhiqizo uhloselwe ukuthi usatshalaliswe njengomkhiqizo osongwe, uzophinda ungene ku-SSHE ngaphambi kokuthi uzinze kushubhu yokuphumula ngaphambi kokusonga. Uma umkhiqizo ugcwele izinkomishi, alikho ithubhu lokuphumula elifakwe kulayini we-crystallization.

UKUPAKISHA, UKUGCINA NOKUKHUMBULA ( IZONE 5 )

Imishini ehlukahlukene yokupakisha nokugcwalisa iyatholakala emakethe futhi ngeke ichazwe kulesi sihloko. Nokho, ukuvumelana komkhiqizo kuhluke kakhulu uma ukhiqizwa ukuze upakishwe noma ugcwaliswe. Kusobala ukuthi umkhiqizo opakishiwe kufanele ubonise ukuthungwa okuqinile kunomkhiqizo ogcwalisiwe futhi uma lokhu kuthungwa kungasebenzi kahle umkhiqizo uzophambukiselwa ohlelweni lokuncibilika kabusha, uncibilike bese wengezwa ku-buffer tank ukuze ucutshungulwe kabusha. Izinhlelo ezihlukene zokunyibilikisa ziyatholakala kodwa izinhlelo ezisetshenziswa kakhulu yi-PHE noma i-low pressure SSHE.

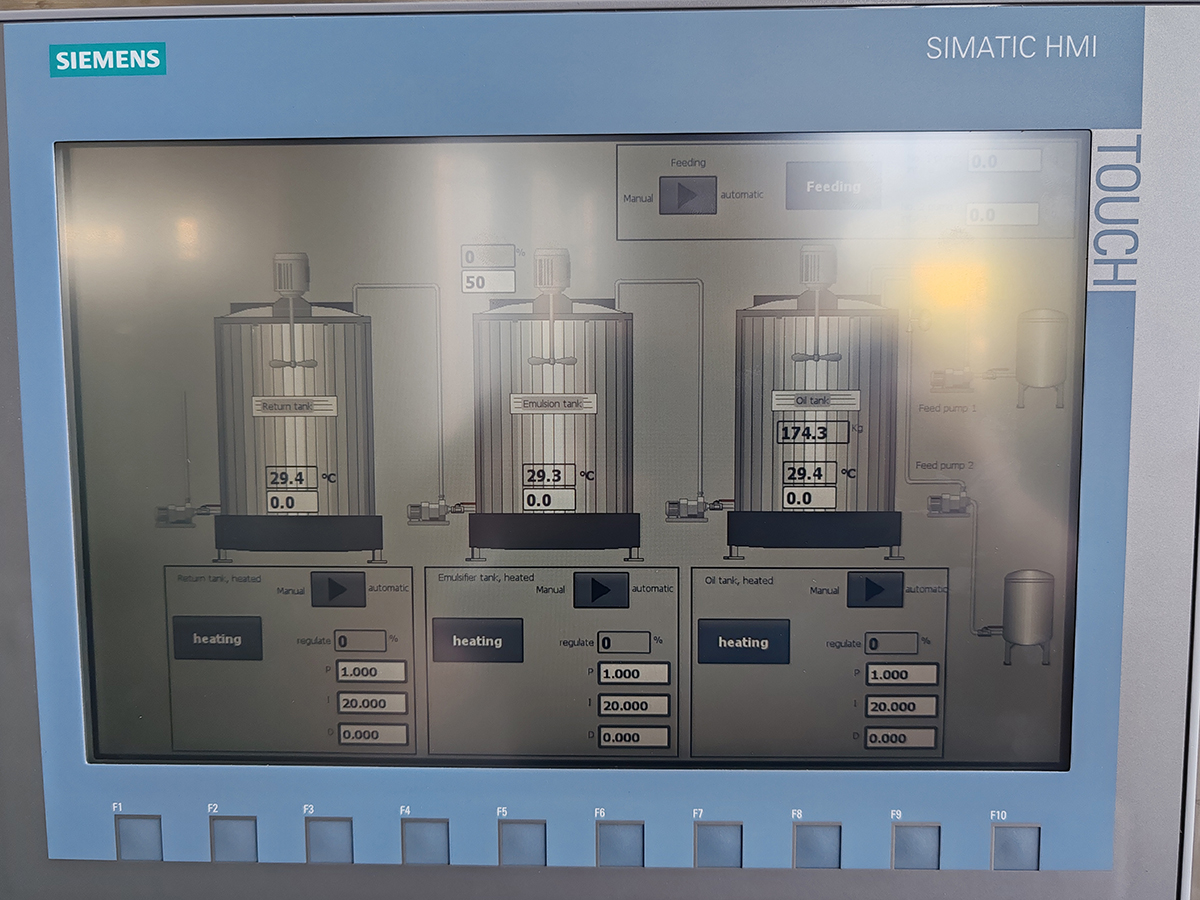

UKUZENZAKALELAYO

Imajarini, njengeminye imikhiqizo yokudla, isemafektri amaningi namuhla akhiqizwa ngaphansi kwezinqubo eziqinile zokulandela umkhondo. Lezi zinqubo ngokuvamile zihlanganisa izithako, ukukhiqizwa kanye nomkhiqizo wokugcina akuphumeleli nje kuphela ekuphepheni kokudla okuthuthukisiwe kodwa futhi nekhwalithi yokudla engaguquki. Izimfuno zokulandeleka zingasetshenziswa ohlelweni lokulawula lwefekthri futhi uhlelo lokulawula lwe-Shiputec luklanyelwe ukulawula, ukuqopha nokubhala phansi izimo ezibalulekile kanye nemingcele ephathelene nenqubo ephelele yokukhiqiza.

Isistimu yokulawula ifakwe ukuvikelwa kwephasiwedi futhi ifaka phakathi ukuloga kwedatha yomlando yawo wonke amapharamitha ahilelekile emugqeni wokucubungula imajarini kusukela kulwazi lweresiphi kuya ekuhlolweni kokugcina komkhiqizo. Ukungena kwedatha kufaka phakathi umthamo kanye nokukhishwa kwepompo yokucindezela okuphezulu (l/ihora nokucindezela emuva), amazinga okushisa omkhiqizo (okubandakanya inqubo ye-pasteurization) ngesikhathi se-crystallization, amazinga okushisa okupholisa (noma ukupholisa izingcindezi zemidiya) ye-SSHE, isivinini se-SSHE nemishini ye-pin rotor kanye nomthwalo wamamotho asebenzisa iphampu yokucindezela okuphezulu, i-SSHE kanye nemishini ye-pin rotor.

Isistimu yokulawula

Ngesikhathi sokucubungula, ama-alamu azothunyelwa ku-opharetha uma imingcele yokucubungula yomkhiqizo othize ingaphandle kwemikhawulo; lezi zisethwe kumhleli weresiphi ngaphambi kokukhiqiza. Lawa ma-alamu kufanele avunywe ngesandla futhi kufanele kuthathwe izinyathelo ngokwezinqubo. Wonke ama-alamu agcinwa ohlelweni lwe-alamu lomlando ukuze lubukwe kamuva. Uma umkhiqizo ushiya umugqa wokukhiqiza usesimweni esipakishwe ngokufanelekile noma esigcwaliswe, ungaphandle kwegama lomkhiqizo ngokuvamile elimakwa ngedethi, isikhathi kanye nenombolo kamazisi yenqwaba ukuze kulandelelwe kamuva. Umlando ophelele wazo zonke izinyathelo zokukhiqiza ezihilelekile ohlelweni lokukhiqiza ufakwa ngaleyo ndlela ukuze kuvikeleke umkhiqizi kanye nomsebenzisi wokugcina, umthengi.

I-CIP

Izitshalo zokuhlanza i-CIP (CIP = ukuhlanzwa endaweni) nazo ziyingxenye yesikhungo semajarini yesimanje njengoba izitshalo ezikhiqiza imajarini kufanele zihlanzwe njalo. Emikhiqizweni yemajarini yendabuko kanye ngesonto isikhathi sokuhlanza esivamile. Kodwa-ke, emikhiqizweni ebucayi efana namafutha aphansi (okuqukethwe kwamanzi amaningi) kanye/noma amaprotheni aphezulu aqukethe imikhiqizo, izikhawu ezimfushane phakathi kwe-CIP ziyanconywa.

Empeleni, kusetshenziswa izinhlelo ezimbili ze-CIP: Izitshalo ze-CIP ezisebenzisa imidiya yokuhlanza kanye kuphela noma izitshalo ezinconyiwe ze-CIP ezisebenza ngesixazululo se-buffer semidiya yokuhlanza lapho imidiya efana ne-lye, i-asidi kanye/noma izibulala-magciwane zibuyiselwa kumathange okugcina e-CIP ngamanye ngemva kokusetshenziswa. Le nqubo yakamuva iyakhethwa njengoba imele isisombululo esivumelana nemvelo futhi iyisixazululo esiyongayo mayelana nokusetshenziswa kwama-ejenti okuhlanza ngakho-ke izindleko zawo.

Uma kwenzeka imigqa yokukhiqiza eminingana ifakwe efekthri eyodwa, kungenzeka ukusetha amathrekhi okuhlanza ahambisanayo noma amasistimu wesathelayithi e-CIP. Lokhu kuphumela ekuncipheni okukhulu kwesikhathi sokuhlanza nokusetshenziswa kwamandla. Amapharamitha wenqubo ye-CIP alawulwa ngokuzenzakalelayo futhi afakwe ukuze alandelelwe kamuva ohlelweni lokulawula.

AMAZWI OKUGCINA

Lapho ukhiqiza imajarini nemikhiqizo ehlobene nayo, kubalulekile ukukhumbula ukuthi akuzona kuphela izithako ezifana namafutha namafutha asetshenzisiwe noma iresiphi yomkhiqizo enquma ikhwalithi yomkhiqizo wokugcina kodwa futhi nokumiswa kwesitshalo, imingcele yokucubungula kanye nesimo sesitshalo. Uma ulayini noma izinto zokusebenza zinganakekelwa kahle, kunengozi yokuthi ulayini awusebenzi kahle. Ngakho-ke, ukukhiqiza imikhiqizo yekhwalithi ephezulu, isitshalo esisebenza kahle siyadingeka kodwa ukukhetha inhlanganisela yamafutha nezici ezihambisana nokusetshenziswa kokugcina komkhiqizo nakho kubalulekile kanye nokumisa okulungile nokukhetha kwemingcele yokucubungula yesitshalo. Okokugcina umkhiqizo wokugcina kufanele welashwe ngokusetshenziswa kokugcina.

Isikhathi sokuthumela: Dec-19-2023