Isifinyezo

I-margarine yama-pastry kumele ibe yipulasitiki futhi iqine. Ukugeleza kobuchwepheshe bokukhiqiza i-margarine yama-pastry kungahlelwa kalula yi-tubularchiller (i-tubular scraped surface heat exchanger). Ngesikhathi sokucubungula uwoyela ngokujulile, ukupholisa kunethonya elikhulu ekukhanyeni kwe-margarine yama-pastry. I-margarine ehlukene idinga inqubo ehlukile kanye nesimo sokushisa.

I-margarine yama-pastry kumele ibe yipulasitiki futhi iqine. Ukugeleza kobuchwepheshe bokukhiqiza i-margarine yama-pastry kungahlelwa kalula yi-tubularchiller (i-tubular scraped surface heat exchanger). Ngesikhathi sokucubungula uwoyela ngokujulile, ukupholisa kunethonya elikhulu ekukhanyeni kwe-margarine yama-pastry. I-margarine ehlukene idinga inqubo ehlukile kanye nesimo sokushisa.

Amagama ayisihluthulelo: i-pastry margarine; i-cooling drum; i-tube chiller, i-scraped heat exchanger, ukukhiqizwa kwe-margarine.

Ukwethulwa kobuchwepheshe be-tube chiller

Nakuba imikhiqizo ye-margarine egobile ibilokhu ikhiqizwa iminyaka eminingi, abantu bebelokhu bezama ukuthola indlela engcono kakhulu yezimo zenqubo, ikakhulukazi ekubunjweni kwefomula yomkhiqizo ehlukene ngaphansi kwezimo ezahlukene zokucubungula. Ngaphambi kokusungulwa kwe-scraper heat exchanger, noma umshini wokucima ityhubhu, yonke imikhiqizo ye-margarine yayikhiqizwa kusetshenziswa imishini yokucima i-drum kanye neyokuxova. Ngenxa yomshini wokucubungula i-tube quenching unezinzuzo eziningi uma kuqhathaniswa neminye imishini yokucubungula, ngakho-ke manje abakhiqizi be-margarine basebenzisa ukukhiqizwa kwayo kwe-margarine ye-pastry egobile, leli phepha elimayelana nomshini wokucubungula ithubhu yokucima ukukhiqiza inqubo ye-margarine ye-pastry egobile ukwenza isingeniso esithile.

Izakhiwo eziyinhloko ze-margarine eqhekekile ukuqina kwayo kanye nokuqina kwayo. Uma i-margarine igoqwa futhi igoqwa ngokuphindaphindiwe, izendlalelo kumele zihlale zingaphuki enhlameni, ngakho-ke ukuqina kubalulekile; Ukuzinza nakho kubalulekile. Uma i-margarine ingaqinile ngokwanele ukuba ithambe noma ikwazi ukungena uwoyela, futhi imuncwa enhlameni, ungqimba lwamafutha phakathi kwezingqimba zenhlama luzoncipha kakhulu.

Isakhiwo somshini wokucima izigubhu ojikelezayo silula, kudingeka nje ukulungisa amapharamitha ambalwa ekukhiqizeni angakhiqiza imikhiqizo ye-margarine ecwebezelayo. I-margarine yama-pastry eqhekekile ekhiqizwa umshini wokucima izigubhu inobucwebe obuhle, akulula ukungena ku-oyela, futhi izinzile kakhulu ebangeni lokushisa elikhulu. Umshini wokucima izigubhu kunomshini wokucima izigubhu ekusebenzeni kahle uye wathuthuka kakhulu, okubonakala kakhulu ku:

(1) Emikhiqizweni yokucubungula amapayipi avaliwe, ukuvalwa okuhle, izimo zokuhlanzeka nazo zizothuthuka kakhulu;

(2) Ukuqaphela ukusebenza komfutho ophezulu, okubaluleke kakhulu ekukhiqizweni kwe-margarine ecwebezelayo;

(3) Ukuguquguquka okuhle, kungashintsha isivinini, ingcindezi, amandla okuqandisa kanye nezinye izimo zokucubungula ngendlela eguquguqukayo.

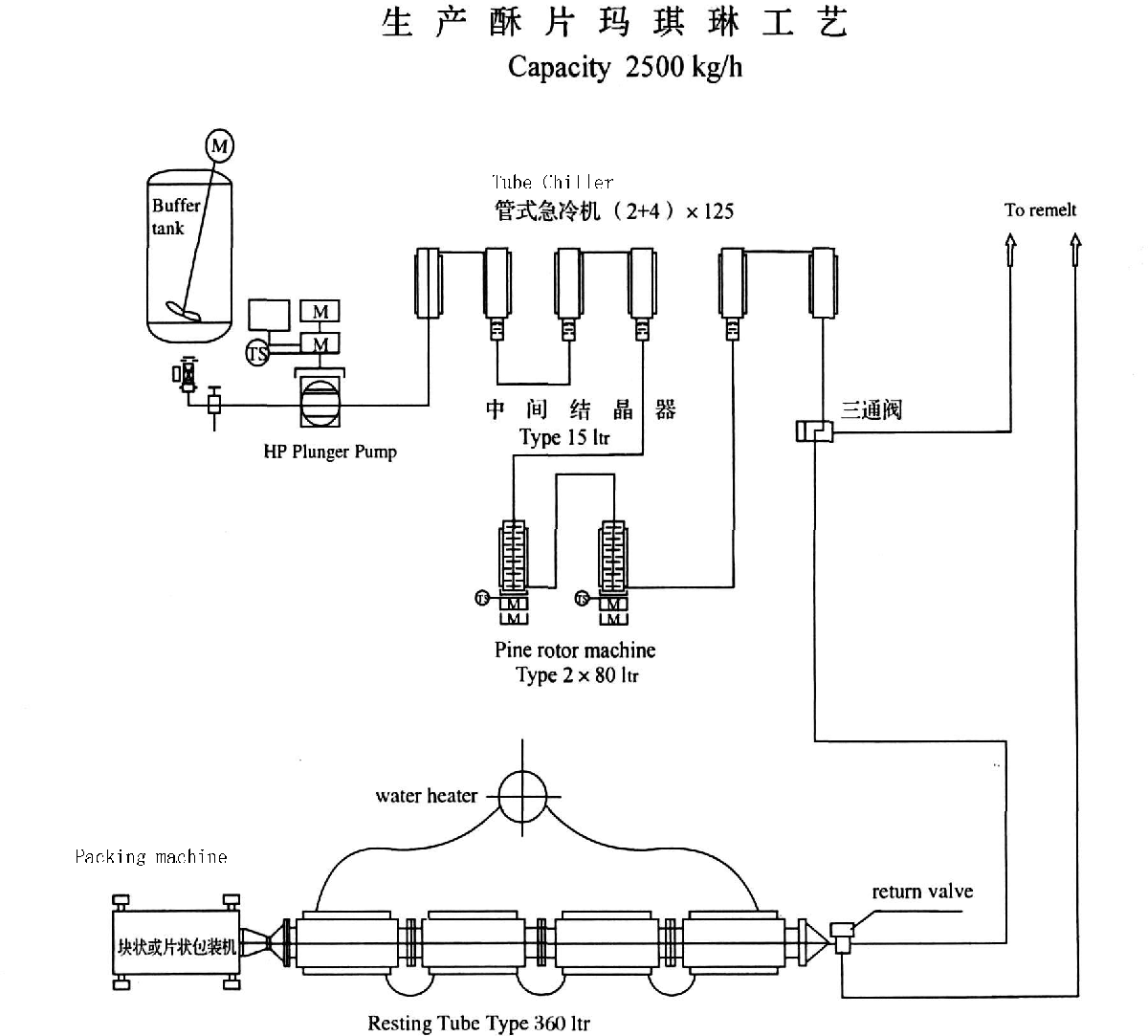

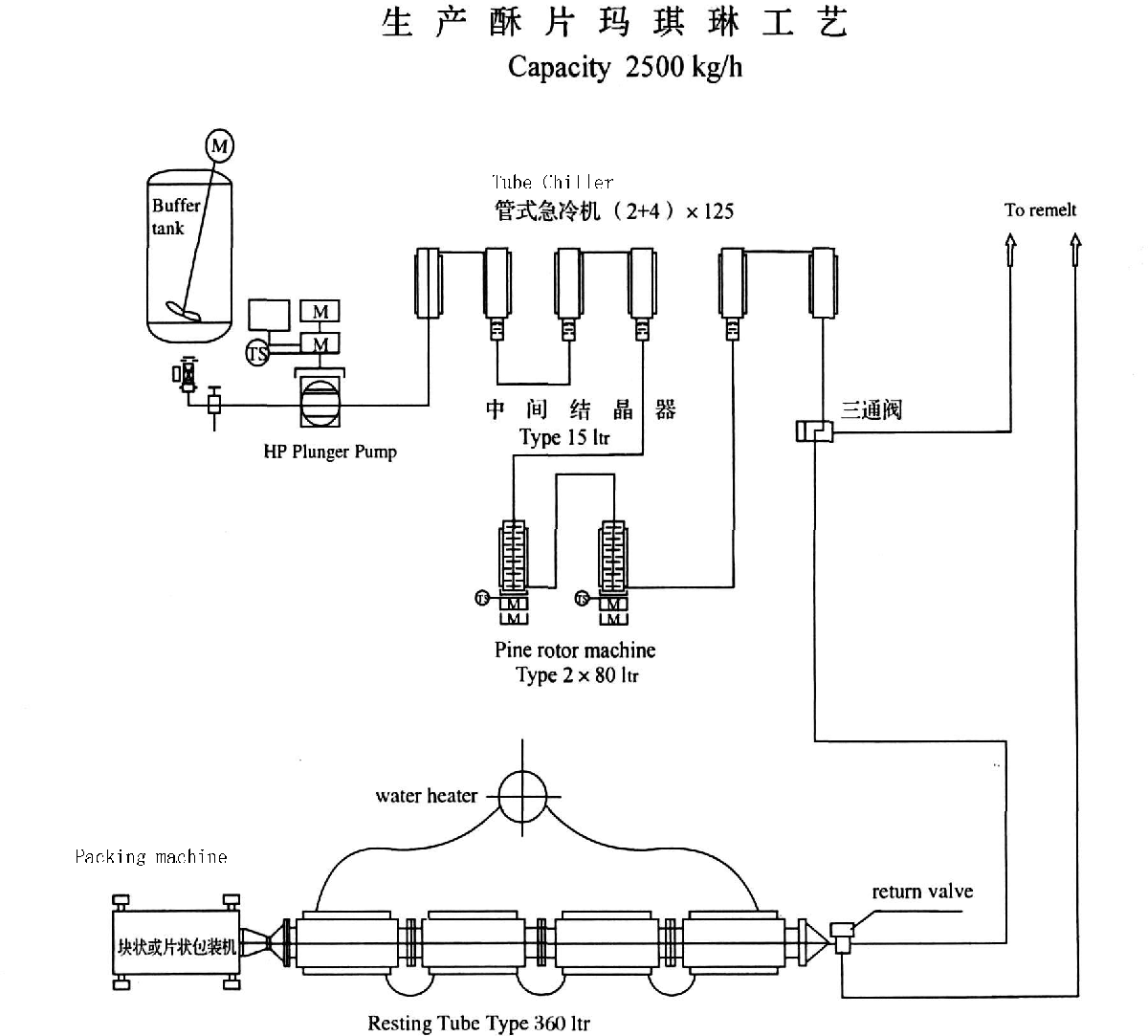

Inqubo emele ukukhiqizwa kwe-margarine ye-pastry eqhekekile ngomshini wokucima amashubhu imi kanje:

Iphampu ye-plunger enomfutho ophezulu ※ I-tubular scraped heat exchanger enomfutho ophezulu (Iyunithi A) ※ Isethi ye-crystallizer ephakathi ※ Umshini we-stirring pine rotor (Iyunithi B) ※ Ithubhu lokuphumula elikhulu ※ Ukupakisha izingcezu/amabhlogo.

Umsebenzi we-crystallizer ephakathi nendawo ulingana nowe-kneader yokuxuba. Itholakala epayipini lokucima lomshini wokucubungula futhi iqhutshwa ukuze ijikelezwe yi-cutter shaft yomshini wokucubungula.

Kulula ukulungisa ukuhamba kokucubungula komkhiqizo ukuze ukhiqize i-margarine ye-pastry eqhekekile ngomshini wokucima ishubhu. Inhloso yokulungisa inqubo ingafezwa ngokushintsha imodi yokuxhuma yepayipi yokuxhuma phakathi kweqembu lepayipi yokucima (iyunithi A) kanye neyunithi yokuxova (iyunithi B), okulula ukuyisebenzisa. Isibonelo, iyunithi yokuxova evuselelayo (iyunithi B) ingafakwa phakathi kwepayipi yokucima yeyunithi A, kulandela ukugeleza kwe-A 1 ※A 2 ※B1 ※B2 ※A 3 ※A 4, noma ukushintsha ukugeleza kwe-A 1 ※A 2 ※A 3 ※A 4 ※B1 ※B2. Ngokushintsha nje inqubo yokucubungula kungathuthukisa ikhwalithi yomkhiqizo. Enqubweni engenhla, inqubo yokubeka iyunithi B phakathi kwepayipi yokucima yeyunithi A ifaneleka kakhulu ekwakhiweni kwamafutha emifino okusekelwe kumafutha esundu, okuye kwafakazelwa izikhathi eziningi emisebenzini yokukhiqiza. Futhi uma izinto eziyinhloko zomkhiqizo ziyizinkomo, imiphumela engcono ingatholakala ngokubeka iyunithi B ngemuva kweyunithi A.

Umthamo wokuxova unqunywa ukwakheka komkhiqizo, isibonelo, umthamo omkhulu wokuxova kufanele usetshenziswe ekwakhiweni kwamafutha nge-crystallization ehamba kancane. Enqubweni yokukhiqiza ipayipi yokupholisa okusheshayo, umphumela wokuxova umthamo weqembu eliphakathi kanye nomthamo we-crystallizer bese ushaya iyunithi yokuxova (B) isamba somthamo weyunithi, ngakho-ke lapho ushintsho kufomula yomkhiqizo, kudingeka lulungiswe umthamo wenqubo yokuxova, kungaba ngokwanda noma ukwehla komthamo weyunithi ye-B, kunganda noma kunciphe kumthamo wesikhunta esiphakathi. Kungenziwa ngisho nangokungeza nokususa ngesikhathi esifanayo, kuguquguquka kakhulu.

Umthamo wokuxova unqunywa ukwakheka komkhiqizo, isibonelo, umthamo omkhulu wokuxova kufanele usetshenziswe ekwakhiweni kwamafutha nge-crystallization ehamba kancane. Enqubweni yokukhiqiza ipayipi yokupholisa okusheshayo, umphumela wokuxova umthamo weqembu eliphakathi kanye nomthamo we-crystallizer bese ushaya iyunithi yokuxova (B) isamba somthamo weyunithi, ngakho-ke lapho ushintsho kufomula yomkhiqizo, kudingeka lulungiswe umthamo wenqubo yokuxova, kungaba ngokwanda noma ukwehla komthamo weyunithi ye-B, kunganda noma kunciphe kumthamo wesikhunta esiphakathi. Kungenziwa ngisho nangokungeza nokususa ngesikhathi esifanayo, kuguquguquka kakhulu.

Isikhathi sokuthunyelwe: Disemba 30-2021