Umugqa Wokucubungula I-Puff Pastry Margarine

Umugqa Wokucubungula I-Puff Pastry Margarine

Ividiyo Yokukhiqiza:https://www.youtube.com/watch?v=3cSJknMaYd8

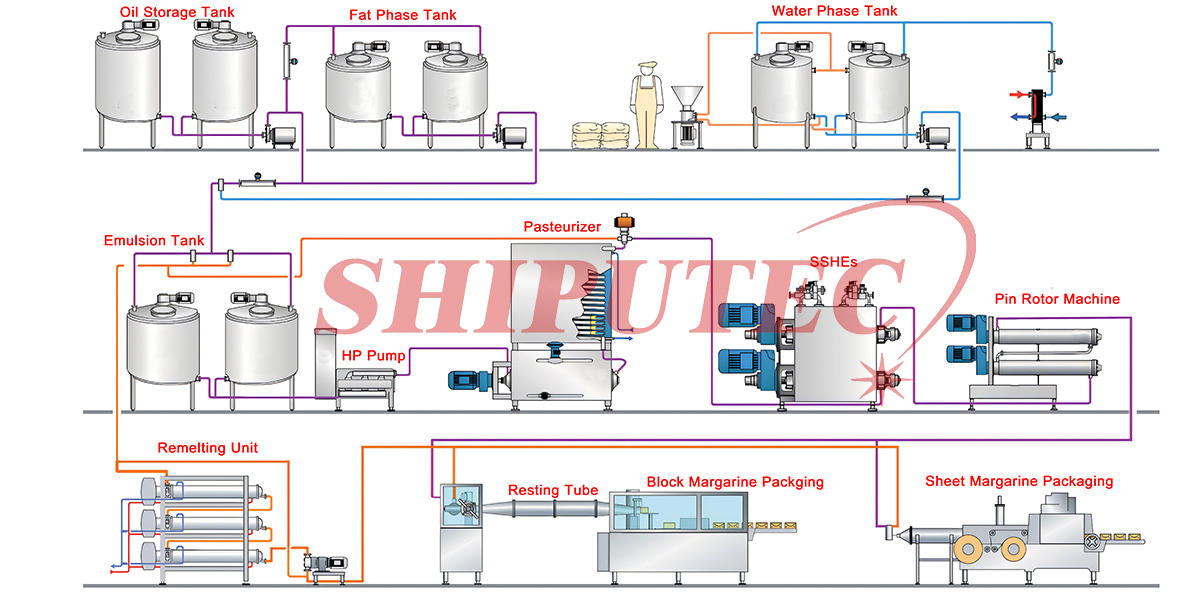

I-margarine iyinto ethatha indawo yebhotela eyenziwe ngamafutha emifino, amafutha ezilwane noma eminye imithombo yamafutha. Inqubo yayo yokukhiqiza kanye nemishini yokucubungula isivuthiwe kakhulu ngemva kweminyaka yokuthuthukiswa. Okulandelayo ukugeleza kwenqubo okuningiliziwe kanye nokwethulwa kwemishini ebalulekile:

I. Inqubo Yokukhiqiza I-Margarin

1. Ukulungiswa Kwezinto Ezingavuthiwe

• Izinto zokusetshenziswa eziyinhloko:

o Amafutha (cishe angu-80%): njengamafutha esundu, amafutha kasoya, amafutha e-rapeseed, amafutha kakhukhunathi, njll., okudingeka ahlungwe (ukususa i-gum, ukususa i-asidi, ukususa umbala, ukususa iphunga).

o Isigaba samanzi (cishe u-15-20%): ubisi olukhishwe amafutha amaningi, amanzi, usawoti, ama-emulsifier (njenge-lecithin, i-mono-glyceride), izithasiselo (njenge-potassium sorbate), amavithamini (njenge-vitamin A, D), izinongo, njll.

o Izithasiselo: umbala (β-carotene), isilawuli se-acidity (i-lactic acid), njll.

2. Ukuxuba kanye nokuhlanganisa

• Ukuxuba isigaba samafutha kanye nesigaba samanzi:

o Isigaba samafutha (izithasiselo ezincibilika ku-oyela + uwoyela) sishiswa sibe ngu-50-60℃ bese sincibilikiswa.

o Isigaba samanzi (amanzi + izithasiselo ezincibilika emanzini) siyashiswa futhi sihlanzwe (ukufakwa kwe-pasteurization, 72℃/15 seconds).

o Izigaba ezimbili zixutshwa ngokulingana, bese kufakwa ama-emulsifier (njenge-mono-glyceride, i-soy lecithin) bese kwakheka i-emulsion efanayo (uhlobo lwamanzi-ku-oyili noma uhlobo lwamafutha-ku-oyili) ngokuxubha ngesivinini esikhulu (2000-3000 rpm).

3. Ukupholisa okusheshayo kanye nokwenza i-crystallization (Isinyathelo Esiyinhloko)

• Ukupholisa okusheshayo: I-emulsion ipholiswa ngokushesha ibe yi-10-20℃ nge-scraped surface heat exchanger (SSHE), okubangela ukwakheka kwekristalu okuyingxenye yamafutha ukuze kwakheke isimo sekristalu se-β' (isihluthulelo sokuthungwa okuhle).

• Ukubumba: Amafutha aqinile kancane agundwa ngomshini ngokusebenzisa umshini wokuxova (i-Pin Worker) ngesivinini esingu-2000-3000 rpm ukuze kuphulwe amakristalu amakhulu futhi kwakhiwe isakhiwo senethiwekhi yamafutha esincane nesilinganayo, kugwenywe umuzwa wokugcwala.

4. Ukuvuthwa Nokupakisha

• Ukuvuthwa: Kushiywa ku-20-25℃ amahora angu-24-48 ukuze kuqiniswe isakhiwo sekristalu.

• Ukupakisha: Kugcwaliswa njengamabhulokhi, izinkomishi, noma uhlobo lokufafaza, bese kugcinwa esiqandisini (i-margarine ethambile ingagcinwa ngqo ekushiseni kwegumbi).

II. Imishini Yokucubungula Eyinhloko

1. Imishini Yokwelashwa Ngaphambi Kokwelashwa

• Imishini yokucwenga uwoyela: i-centrifuge yokususa i-gum, umbhoshongo wokususa i-asidi, ithangi lokususa umbala, umbhoshongo wokususa iphunga.

• Imishini yokucubungula isigaba samanzi: umshini wokugcoba, i-homogenizer enomfutho ophezulu (esetshenziselwa ubisi noma i-homogenizer yesigaba samanzi).

2. Imishini Yokwenza I-Emulsification

• Ithangi le-emulsion: ithangi lensimbi engagqwali elinomsebenzi wokuxuba nokushisa (njenge-paddle noma i-turbine type stirrer).

• I-homogenizer enomfutho ophezulu: thuthukisa amaconsi e-emulsion (umfutho ongu-10-20 MPa).

3. Imishini Yokupholisa Ngokushesha

• I-Scraped Surface Heat Exchanger (SSHE):

o Ipholisa ngokushesha kuze kube yilapho ibanda kancane, nge-scraper ejikelezayo ukuze kuvinjelwe ukukhuhla.

o Imikhiqizo ejwayelekile: iGerstenberg & Agger (eDenmark), i-Alfa Laval (eSweden), i-SPX flow (e-USA), i-Shiputec (eShayina)

• Isisebenzi se-Pin:

o Gunda amafutha ngokusebenzisa amasethi amaningi ezikhonkwane ukuze ulawule usayizi wekristalu.

4. Imishini Yokupakisha

• Umshini wokugcwalisa ozenzakalelayo: wamabhulokhi (25g-500g) noma ukupakisha imiphongolo (1kg-20kg).

• Umugqa wokupakisha ongcolile: ufanelekela imikhiqizo ehlala isikhathi eside (njenge-margarine ewuketshezi ephathwe nge-UHT).

III. Izinhlobo Zenqubo

1. I-Margarine Ethambile: Ingxenye ephezulu yamafutha acwebezelayo kumafutha (njengamafutha e-sunflower), asikho isidingo sokubumba okusheshayo kokupholisa, ahlanganiswe ngokuqondile futhi ahlanganiswe.

2. I-Margarine enamafutha aphansi: Okuqukethwe kwamafutha okungu-40-60%, kudinga ukwengeza izinto zokujiya (njenge-gelatin, isitashi esiguquliwe).

3. I-Margarine Esekelwe Ezitshalweni: Ifomula kawoyela wezitshalo zonke, awekho ama-trans fatty acids (lungisa iphuzu lokuncibilika ngokusebenzisa ukushintshana kwe-ester noma ubuchwepheshe bokuhlukaniswa).

IV. Amaphuzu Ayinhloko Okulawula Ikhwalithi •

Ifomu lekristalu: Ifomu lekristalu le-β' (elingcono kunefomu lekristalu le-β) lidinga ukulawulwa kwesilinganiso sokucima kanye nokuqina kokuxuba.

• Ukuphepha kwamagciwane: Isigaba samanzi sidinga ukuhlanza ngokuqinile, futhi i-pH kufanele ilungiswe ngaphansi kuka-4.5 ukuze kuvinjelwe amagciwane.

• Ukuqina kwe-oxidation: Faka ama-antioxidants (njenge-TBHQ, i-vitamin E) ukuze ugweme ukungcoliswa kwama-ion ensimbi.

Ngokuhlanganisa izinqubo nemishini engenhla, ukhilimu wokwenziwa wesimanje ungalingisa ukunambitheka kwebhotela ngenkathi uhlangabezana nezidingo zezempilo ezifana ne-cholesterol ephansi namafutha agcwele aphansi. Ifomula nenqubo ethile kudingeka kulungiswe ngokuya ngokuma komkhiqizo (njengokubhaka noma ukusetshenziswa ezindaweni zokudla).

Ukuqaliswa Kwendawo