I-Super Votator ekukhiqizweni kwebhotela kanye nokukhiqizwa kwe-margarine

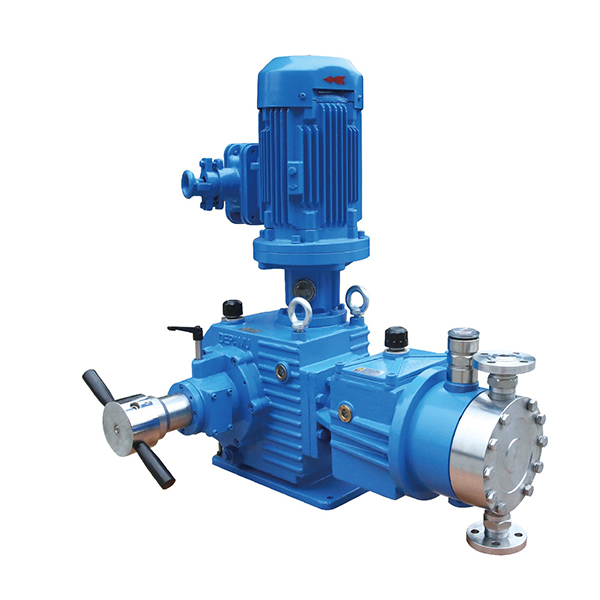

Umsebenzi kanye Nenzuzo ye-Super Votator

Indima Ekukhiqizweni Kwebhotela

Ibhotela liyi-emulsion yamanzi emafutheni (amafutha angama-80%) edinga ukupholisa okulawulwayo kanye ne-crystallization ukuze kube nokuthungwa okuhle kanye nokusabalala kahle.

Izicelo Eziyinhloko:

Ukupholisa Okusheshayo Nokukristalu Kwamafutha

Umvoti upholisa ngokushesha ukhilimu noma ibhotela elicibilikisiwe kusuka ku-~40°C kuya ku-10–15°C, ukukhuthaza ukwakheka kweamakristalu angu-β'(amakristalu amancane, aqinile amafutha aqinisekisa ukuthungwa okubushelelezi).

Ukucheba okuphezulu kuvimbela ukwakheka kwamakristalu amakhulu, kugwema ukuba luhlaza.

Ukusebenza/Ukulungisa

Ezinye izinhlelo zihlanganisa umvoti ne-isisebenzi sephininoma iyunithi yokuxova ukuze kuthuthukiswe ukuthungwa kwebhotela, kuthuthukiswe ukusabalala kwalo kanye nokuzwakala komlomo.

Ukucubungula Okuqhubekayo

Ngokungafani nokushintshana kweqembu okujwayelekile, abavoti bayakuvumelaukukhiqizwa okuqhubekayo okusheshayo, okwandisa ukusebenza kahle kanye nokungaguquguquki.

Izinzuzo Kunezindlela Zendabuko:

Ukupholisa okusheshayo→ Ukulawulwa kwesakhiwo sekristalu okungcono

Ukuhlukaniswa kwamafutha okuncishisiwe→ Umkhiqizo ofanayo kakhulu

Umphumela ophezulu→ Kufanelekela ukukhiqizwa kwezimboni

Indima Ekukhiqizweni Kwe-Margarine

I-margarine (i-emulsion yamafutha emanzini, evame ukususelwa ezitshalweni) ithembele kakhulu kubavoti ekwakheni amafutha kanye nokuqinisa ama-emulsion.

Izicelo Eziyinhloko:

Ukupholisa i-Emulsion kanye ne-Crystallization

Ingxube yamafutha (isb., amafutha esundu, isoya, noma i-sunflower) ixutshwe ne-hydrogen noma ithakazelelwe ukuze kufezwe iphrofayili yokuncibilika oyifunayo.

Umvoti upholisa ngokushesha i-emulsion (~45°C →5–20°C) ngaphansi kokugunda okuphezulu, okwakhaamakristalu angu-β'(ilungele ukushelela, ngokungafani namakristalu e-β, abangela ukugcwala kwenhlabathi).

Ukulawula Ukwakheka Kwepulasitiki Nokusabalala

Ukulungisaizinga lokupholisa, amandla okusika, kanye nengcindeziiguqula ubulukhuni, okwenza ifanelekele ukusetshenziswa okuhlukene (isb., i-margarine yetafula vs. i-margarine yebhaka).

Izinhlobo Ezinamafutha Aphansi Nezingenawo Ubisi

Abavoti abakhulu basiza ekuqiniseni i-emulsion yamanzi ku-oyiliukusabalala kwamafutha aphansi(40–60% amafutha) ngokuqinisekisa ukwakheka kahle kwekristalu nokuvimbela ukuhlukaniswa kwesigaba.

Izinzuzo Ekukhiqizweni Kwe-Margarine:

Kuvimbela amakristalu amabi→ Ukuthungwa okubushelelezi

Ivumela ukwakheka okuguquguqukayo(okusekelwe ezitshalweni, okungenawo amafutha angenawo, njll.)

Kuthuthukisa ukuzinza kokuphila kweshelufungokwenza ngcono inethiwekhi yamakristalu amafutha

Izinzuzo Zobuchwepheshe Zabavoti Abaphezulu

| Isici | Inzuzo |

| Ukuklwebha okuphezulu | Kuvimbela ukungcola, kuqinisekisa ukudluliselwa kokushisa okufanayo |

| Ukulawula izinga lokushisa okunembile | Ithuthukisa ukwakheka kwama-fat crystallization (β' vs. β) |

| Ukumelana nengcindezi (kufika kubha engu-40) | Iphatha amafutha aqinile ngaphandle kokuwahlukanisa |

| Ukusebenza okuqhubekayo | Ukusebenza kahle okuphezulu kunokucubungula kwe-batch |

| Idizayini yokuzihlanza | Kunciphisa isikhathi sokungasebenzi sokulungisa |

Izibonelo Zemboni

Ukukhiqizwa Kwebhotela:

I-APV, iGerstenberg Schröder, i-Alfa Laval kanye neShiputec banikeza abavoti bemigqa yokwenza ibhotela eqhubekayo.

I-Margarine/Ukusabalala:

Kusetshenziswe ku-i-margarine esekelwe ezitshalweni(isib., okwenziwe ngamafutha esundu noma kakhukhunathi) ukuze kulingise indlela yokuncibilika kwebhotela lobisi.

Izinto Ezibalulekile Okufanele Uzicabangele Zokuthuthukisa

Izinga lokupholisa kanye namandla okugundakumele kulungiswe ngokusekelwe ekwakhiweni kwamafutha.

Izikrweqe ezigugileukunciphisa ukusebenza kahle → Ukugcinwa njalo kubalulekile.

Izilungiselelo zokucindezelakuthinta ukuqina kwe-emulsion (ikakhulukazi ekusakazeni kwamafutha aphansi).

Isiphetho

Abavoti abakhulu banjalookubalulekileekukhiqizweni kwebhotela ne-margarine yesimanje, okuvumela:

Ukucubungula okusheshayo nokuqhubekayo

Ukulawula ukuthungwa okuphezulu(akukho ukusanhlamvu, ukusabalala okuhle kakhulu)

Ukuguquguquka kwezakhi zobisi nezezitshalo

Ngokwenza ngcono ukupholisa kanye nokwenza amakristalu, baqinisekisa ikhwalithi ehambisanayo emikhiqizweni enamafutha amaningi ngenkathi behlangabezana nezidingo zezimboni.

Izinsizakusebenza Ezengeziwe

A) Izihloko Zokuqala:

Ama-Scraped Heat Exchanger, Ukubuyekezwa Okubalulekile Kwesayensi Yokudla Nokudla Okunomsoco, Umqulu 46, Inkinga 3

UChetan S. Rao noRichard W. Hartel

Landa ingcaphunohttps://www.tandfonline.com/doi/abs/10.1080/10408390500315561

B) Izihloko Zokuqala:

Ama-Margarine, i-ULLMANN'S Encyclopedia of Industrial Chemistry, i-Wiley Online Library.

U-Ian P. Freeman, uSergey M. Melnikov

Landa ingcaphuno:https://onlinelibrary.wiley.com/doi/abs/10.1002/14356007.a16_145.pub2

C) Uchungechunge lwe-SPV Imikhiqizo efanayo yokuncintisana:

Izishintshi Zokushisa Ezingaphezulu Ezikhuhliwe ze-SPX Votator® II

www.SPXflow.com

Vakashela Isixhumanisi:https://www.spxflow.com/products/brand?types=heat-exchangers&brand=waukesha-cherry-burrell

D) Uchungechunge lwe-SPA kanye nochungechunge lwe-SPV Imikhiqizo efanayo yokuncintisana:

Izishintshi Zokushisa Ezingaphezulu Ezikhuhliwe

www.alfalaval.com

Vakashela Isixhumanisi:https://www.alfalaval.com/products/heat-transfer/scraped-surface-heat-exchangers/scraped-surface-heat-exchangers/

E) Uchungechunge lwe-SPT Imikhiqizo efanayo yokuncintisana:

I-Terlotherm® Izishintshi Zokushisa Ezingaphezulu Ezikhuhliwe

www.proxes.com

Vakashela Isixhumanisi:https://www.proxes.com/en/products/machine-families/heat-exchangers#data351

F) Uchungechunge lwe-SPSV Imikhiqizo efanayo yokuncintisana:

Izishintshi Zokushisa Ezingaphezulu Ezikhuhliwe ze-Perfector ®

www.gerstenbergs.com/

Vakashela Isixhumanisi:https://gerstenbergs.com/polaron-scraped-surface-heat-exchanger

G) Uchungechunge lwe-SPSV Imikhiqizo efanayo yokuncintisana:

I-Ronothor® Izishintshi Zokushisa Ezingaphezulu Ezikhuhliwe

www.ro-no.com

Vakashela Isixhumanisi:https://ro-no.com/en/products/ronothor/

H) Uchungechunge lwe-SPSV Imikhiqizo efanayo yokuncintisana:

I-Chemetator® Izishintshi Zokushisa Ezingaphezulu Ezikhuhliwe

www.tmcigroup.com

Vakashela Isixhumanisi:https://www.tmcigroup.com/wp-content/uploads/2017/08/Chemetator-EN.pdf

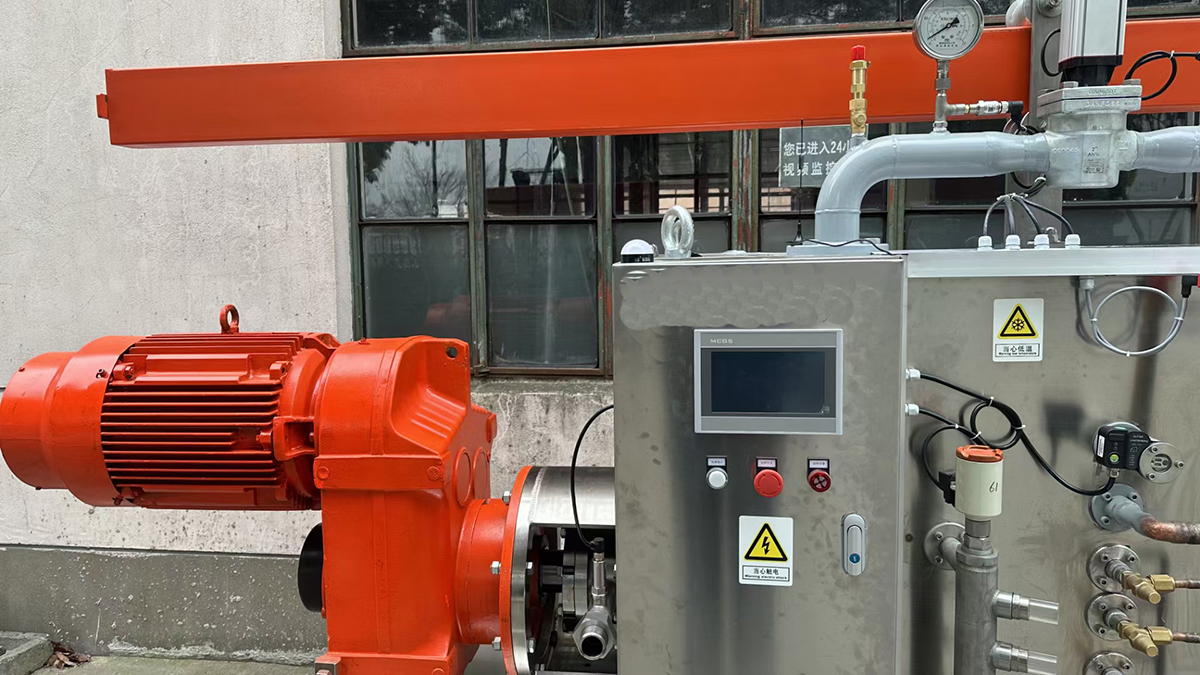

Ukuqaliswa Kwendawo